Project Overview

Client’s Chennai facility was generating about 50KLD of sewage on a daily basis. The sewage was being treated in a conventional Activated Sludge Process (ASP) wastewater system. The ASP system was more than a decade old and quite timeworn. It was reaching its limits with frequent breakdowns, and continuously failing to deliver the desired output quality.

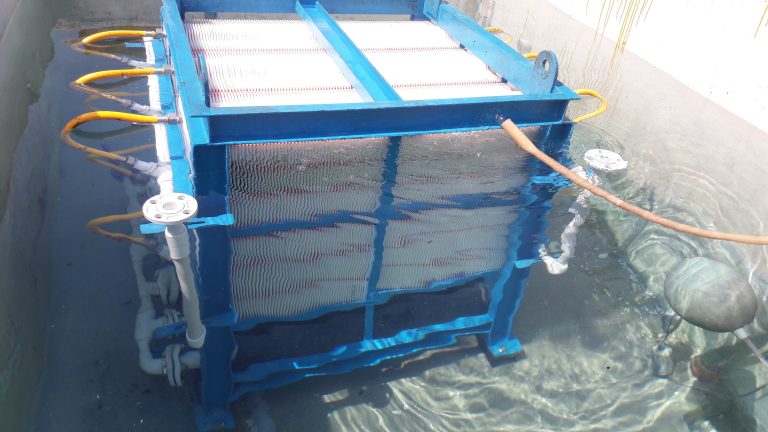

The client had meanwhile added more workforce, and was exploring a brand new sewage treatment plant of an increased capacity of 60 KLD. Their requirement was for a system that would effectively treat the sewage and produce high quality water that could be reused in their process, be able to meet the Pollution Control Board (PCB) norms, and also reduce their raw water intake. Client evaluated and finally chose a membrane bio-reactor (MBR) solution, due to its capability of minimizing unit operations while still producing high quality, ultrafil-tration-grade water for their use.