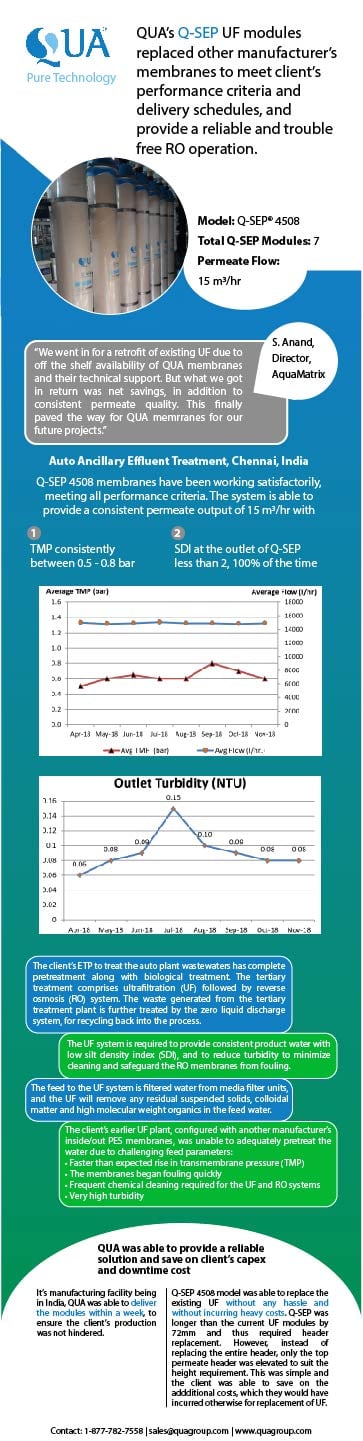

QUA recently completed a project for an automobile manufacturing plant in India. The ultrafiltration membranes were not able to perform due to challenging feed parameters which caused rapid fouling and required frequent cleaning. QUA’s Q-SEP UF membranes replaced the current membranes to meet the client’s performance criteria and delivery schedules, providing a reliable and trouble free RO operation.

The Q-SEP 4508 model was able to replace the existing UF without any hassle and without incurring heavy costs. Q-SEPwas longer than the current UF modules by 72mm and thus required header replacement. However, instead of replacing the entire header, only the top permeate header was elevated to suit the height requirement. This was simple and the client was able to save on the costs which they would have incurred otherwise for replacement of UF. Thus, with Q-SEP, the saving for the client has been on two counts; one, they were able to avoid CIP downtime cost as Q-SEP were delivered immediately, and two, they have saved on capex on account of Q-SEP being almost 40% lower in cost as compared to the other manufacturer’s membranes.

The replaced Q-SEP membranes have been working for the past 6 months with a cross flow rate of 2.0 m3/hr, and the system is able to provide a consistent permeate output of 15m3/hr. The TMP is consistently between 0.5 – 0.8 bar, and SDI at the outlet of Q-SEP is less than 2, 100% of the time.

For the full story, click here.