The Facility

Arabian Industrial Fibers Company is a Saudi Basic Industries Corporation (SABIC) affiliate located in Yanbu Alsinaiyah, KSA that produces aromatics components/derivatives, PTA, acetic acid and polyethylene terephthalate. For its IBN Rushd II expansion project, upon completion of Taiwan’s CTCI installation, Aquatech supplied the demineralized water package. The demineralized water requirement for the existing IBN Rushd complex is supplied by Utility-1 and Utility-2 blocks. Utility-2, which includes three ion exchangers (mixed bed type, 3×50%) and a regeneration and neutralization facility, was also originally supplied by Aquatech.

Project Overview

Demineralized water is mainly used in PTA, boiler feed water make up, boiler chemical dosing package and minor process usage in Sulfolane, Aromatics, and PET II plants. The Utility-1 block supplies the demineralized water requirement for existing PET. Utility-2 supplies the demineralized water requirement for the rest of the complex. In order to provide for the additional DM for IBN Rushd II, modifications were required to this Utility-2 block. Specifications for the new facilities were based on the existing system Utility-2 facilities to minimize cost as well as minimize modifications, and have similarities in terms of operation and maintenance procedures.

Scope of Service

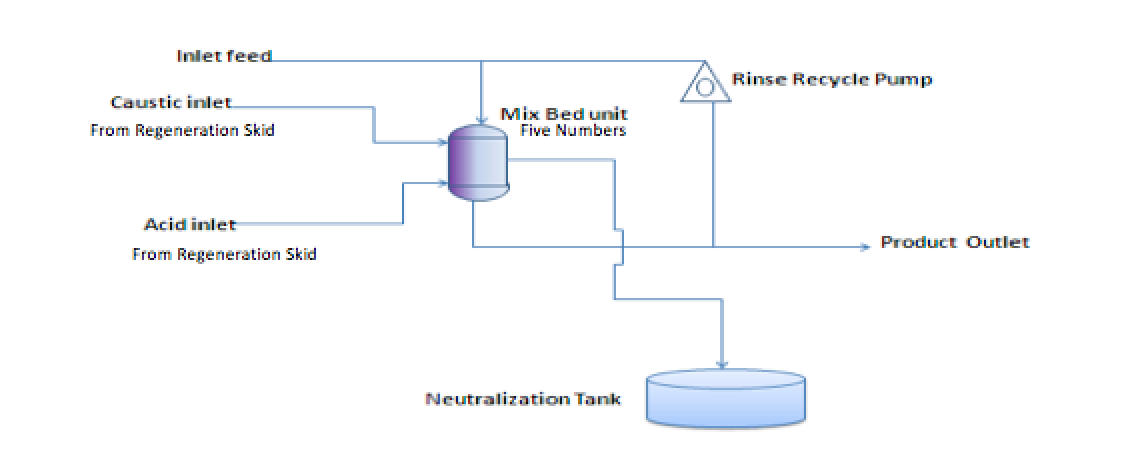

In its demineralized water package, Aquatech has provided mixed bed units to make the water suitable for final use. The scheme includes the addition of two identical mixed bed units to the existing three mixed bed streams that were originally provided by Aquatech. Each mixed bed is designed for 572 GPM (130 m³/hr) (gross service flow). Feed water is passed through the mixed bed in order to bring down dissolved solids. The mixed bed, as the name implies, contains a mixture of both strong acid cation and strong base anion resins in a single vessel, which removes traces of cations and anions; the resultant water being pure demineralized water. Mixed beds are required to be routinely regenerated after a predefined time period with acid and caustic. Aquatech adopted the simultaneous regeneration process for acid as well as caustic, to minimize the wastewater produced during regeneration. Aquatech’s final installed configuration is four working + one standby mixed bed units. With all five mixed beds working, the plant output will be 2860 GPM (650 m³/hr). Normal output of the plant is expected to be 2332 GPM (520 m³/hr).

Design Water AnalysisAt the outlet of mixed bed

| Description | Unit | Outlet |

| Specific Conductivity @ 20 Deg C | μs/cm | 0.1 |

| Chloride | ppm as Cl | ≤ 0.1 |

| Silica | ppm as SiO2 | ≤ 0.1 |

| Turbidity | NTU | Clear |

Process Flow Diagram