Aquatech successfully commissioned a complete makeup water treatment and Zero Liquid Discharge (ZLD) facility at the 582 MW Kemper County Energy project, one of the few Integrated Gasification Combined (IGCC) projects in the United States.

Project Overview

The 582 MW Integrated Gasification Combined Cycle (IGCC) project is located near DeKalb, Mississippi. The plant uses Transport Integrated Gasification (TRIG™) technology which was developed by Southern Company and Kellog Brown & Root.

Supply water for this plant is treated wastewater from the City of Meridian. The site is a Zero Liquid Discharge (ZLD) facility. Therefore, no processed water from this plant is discharged into rivers, creeks or streams.

Southern Company Services purchased a Water and Wastewater System on an EPC basis from Aquatech for Mississippi Power. The concept of this “Water Island” allowed Aquatech to focus on its strength as a design build operator while allowing Southern Company to focus on building the IGCC.

Mississippi Power selected Aquatech as the lowest life cycle cost and most environmentally-friendly option for supplying water to the Kemper County IGCC facility. Aquatech designed, fabricated, erected, started up and will operate for five years a complete makeup water treatment facility and wastewater treatment facilities for this project.

Scope of Work

Aquatech brought to this project its experience in providing water treatment facilities to three of four known IGCC plants in the USA, acting as the single supplier responsible for the design, fabrication, erection, and commissioning of this project, which was done on a DBOM basis with Aquatech engaged to operate the facilities for five years.

Scope of Technology

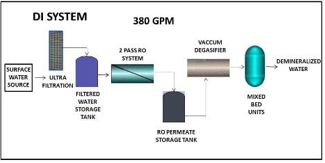

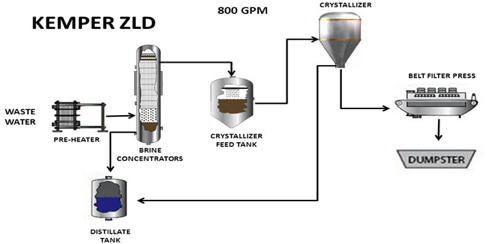

Water Treatment Technologies included ultrafiltration (UF), reverse osmosis (RO), conventional demineralization, and thermal evaporation based ZLD. Aquatech provided the following components:

- Make-up systems 2 X 380 GPM each (86 m³/hr) – UF, RO, mixed bed

- Mobile ion exchange demineralization 700 GPM (151 m³/hr)

- Two trains Brine Concentrator 2 x 50% 400 GPM each (91m³/hr)

- Two trains Forced Circulation Crystallizer 2 x 50% 40 GPM each (9 m³/hr)

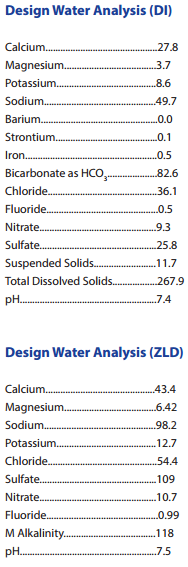

Design Water Analysis (DI)

Process Flow Diagrams