The Facility

Water shortage is usually the problem faced in Gulf countries. Equate Petrochemical Company is Kuwait’s first internationally joint venture company in the petrochemical sector that decided to become the pioneers to explore the possibility of recycling treated wastewater for the internal use in process requirements. Equate Petrochemical Ltd. is the single operator of a fully integrated world-scale manufacturing facility for ethylene, polyethylene and ethylene glycol and their by-products which is marketed throughout The Middle East, Asia, Africa & Europe. The plant is located in water scarce Kuwait and being the first wastewater recovery plant, there was no established data for the offered ultrafiltration/reverse osmosis system. Also, there were heavy fluctuations in turbidity levels varying from 6 NTU to 25 NTU and COD levels varying from 40 ppm to almost 140 ppm.

Project Overview

The objective of this project, which is a part of Equate’s Green Initiative, is to recycle treated wastewater for the internal use in process requirements and to recover and recycle ETP water to the maximum extent possible.

Scope of Service

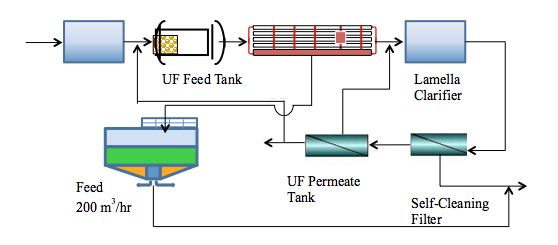

Aquatech designed a scheme to achieve maximum recovery of good water from a wastewater stream of 880 GPM (200 m³/hr). The performance of the scheme with respect to the quantity and quality of the treated recovered water was demonstrated by pilot studies conducted by Aquatech on the actual effluent at the Equate site Aquatech’s complete system offers:

- More than 80% recoveries across Seawater Reverse Osmosis (SWRO)

- More than 90% recoveries across Brackish Water Reverse Osmosis (BWRO)

- More than 80 % recovery overall

Design Water Analysis

| Constituent/Parameter | Unit | Design Basis | Expected Outlet quality | Constituent/Parameter | Unit | Design Basis | Expected Outlet quality | |

| Flow | m3/hr | 200 | 160 | Aluminum | mg/l | 5 | 0 | |

| pH | 6.5-8.5 | 6.5-8.5 | Arsenic | mg/l | 0.1 | 0 | ||

| BOD | mg/l | 30 | <1 | Barium | mg/l | 0.1 | 0 | |

| COD | mg/l | 200 | <3 | Boron | mg/l | 0.75 | < 0.3 | |

| Oil/Grease | mg/l | 10 | 0 | Beryllium | mg/l | 0.1 | 0 | |

| TSS | mg/l | 10 | 0 | Cyanides | mg/l | 0.1 | 0 | |

| TDS | mg/l | 5000 | 65 | Cadmium | mg/l | 0.01 | 0 | |

| Phosphate | mg/l | 2 | 0 | Chromium | mg/l | 0.2 | 0 | |

| Ammonia | mg/l | 5.5 | <1 | Nickel | mg/l | 0.2 | 0 | |

| Nitrate NO3 | mg/l | 30 | <5 | Mercury | mg/l | 0.001 | 0 | |

| TKN | mg/l | 5 | 0 | Cobalt | mg/l | 0.2 | 0 | |

| Total Nitrogen | mg/l | 35 | <6 | Iron | mg/l | 5 | 0.1 | |

| Total Recoverable Phenol | mg/l | 1 | Traces | Antimony | mg/l | 1 | 0 | |

| Fluorides | mg/l | 2 | <0.02 | Copper | mg/l | 0.2 | 0 | |

| Sulfides | mg/l | 0.5 | Traces | Manganese | mg/l | 0.2 | 0 | |

| Chlorine | mg/l | 0.5 | 0.5 | Zinc | mg/l | 2 | 0 | |

| Dissolved Oxygen | mg/l | >2 | n/a | Lead | mg/l | 0.5 | 0 | |

| Turbidity | 50 | Traces | Lithium | mg/l | 2.5 | Traces | ||

| Molybdenum | mg/l | 0.01 | 0 | |||||

| Vanadium | mg/l | 0.1 | 0 | |||||

| Silver | mg/l | 0.1 | 0 | |||||

| All HERBICIDES | mg/l | 0.2 | traces |

Process Flow Diagram