The Facility

China is actively encouraging the growth of coal-to-chemicals in a bid to reduce its dependence on expensive imported natural gas. However, with ecological conservation becoming more important than ever, industries are strictly prohibited from discharging ecologically hazardous waste, including wastewater, originating from such facilities. As a result, Zero Liquid Discharge (ZLD) technologies are increasingly being explored as an alternative wastewater management strategy to reduce environmental impact. This project is a coal-to-chemical facility located in China’s Inner Mongolia province. The Hulunbuir Jinxin Chemical Company Ltd. is established by the joint stock limited company of Yunnan YuntianHua (YTH) and Hong Kong Jinxin Group Company. YTH holds the joint venture company, and they make 500,000 tons/year of ammonia and 80 million tons/year of urea, by transforming coal resources and improving product value-addition.

Project Overview

In the coal-to-chemical facility, the feedwater for brine concentration system plant is from the reject of the waste re-use station (74 m³/h) and blowdown from circulating the cooling tower (25 m³/h). The composite wastewater is rich in contaminants like oil & grease, volatile organic compounds, and has a relatively high COD and TDS of about 16000 mg/l. It also has a high fouling and scaling tendency. As an environmentally conscious corporate entity, YTH’s primary intent has been to treat the rejects from the reverse osmosis system by evaporation/ crystallization so as to achieve ZLD. They also wished to process the combined effluent to recycle the treated soft water for cooling tower make-up and other usages in the plant. The total water to be treated is 110 m³/hr. The only waste allowed from the plant is solid waste in the form of sludge and salt slurry into a solar pond.

Scope of Service

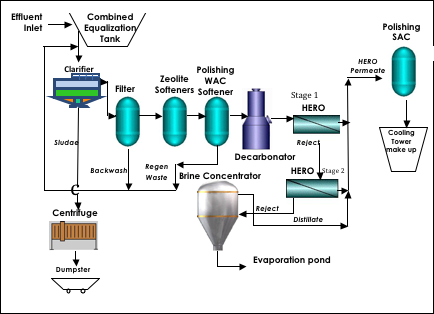

Wastewater heavy in contaminants leads to frequent fouling due to biological and organic compounds in a conventional reverse osmosis membrane system and is thus difficult to treat with any of the conventional effluent recycle and ZLD technologies. For Yuntianhua, Aquatech designed a ZLD System based on the High Efficiency Reverse Osmosis (HERO™) technology, an advanced RO process, wherein the RO section is operated in a high pH environment. The major parameters affecting the RO system operation are kept within limits enabling high (water) recoveries in the range of 82 – 85%. The operating environment of HERO™ system totally eliminates possibility of biological growth, silica scaling and is also resistant to fouling in the membranes, reducing the need for frequent cleaning and thus downtime in the system. Waste streams internally produced by the plant are collected and fully mixed in an equalization tank to ensure proper mixing of the incoming streams. The HERO™ system is used to concentrate the dissolved solids in its reject stream followed by a mechanical vapor compression (MVC) based brine concentrator. The concentrate stream from the BC is taken to the solar pond. With Aquatech’s advanced and reliable technology, the permeate generation is expected to reduce client’s raw water requirements substantially while eliminating the effluent disposal requirements – thus reducing both the carbon footprint as well as the water footprint. The overall recovery of the complete ZLD system at YTH is over 88%.

| Design Water Analysis: Composite Stream | ||

| Parameters | Units | Composite Feed |

| pH | — | 7–8 |

| Total Dissolved Solids | mg/L | ~16000 |

| Biochemical Oxygen Demand (27oC) | mg/L | 30 |

| Chemical Oxygen Demand | mg/L | 244 |

| Hardness as CaCo3 | mg/L | 1000 – 1500 |

| Ammonia as NH3 | mg/L | 30 – 35 |

| Fluorides as F | mg/L | 7–8 |

| Silica as SiO2 | mg/L | 222 |

| Colloidal Silica as SiO2 | mg/L | 40.5 |

| Total suspended solids | mg/L | 45 |

Process Flow Diagram