The Facility

Reliance Group is India’s largest private sector enterprise with businesses spanning exploration and production of oil and gas, petroleum refining and marketing, petrochemicals (polyester, fiber intermediates, plastics and chemicals), textiles, retail and special economic zones. Reliance Industries Limited (RIL), the flagship company, is a Fortune Global 500 company and is the largest private sector company in India. RIL’s Jamnagar Refinery Works is the biggest grassroot refinery in the World. The refinery’s main source of water is the product water produced from sea water by thermal desalination units. This makes water very precious in the facility, and Reliance has a major focus on recycle and reuse of various effluents produced in the refinery.

Project Overview

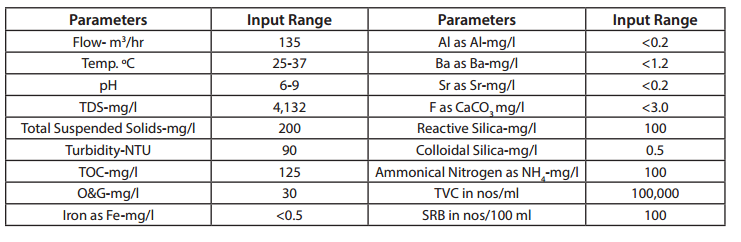

Reliance had an additional requirement of 110 m³/hr of water for cooling tower make-up and horticulture with TDS levels <1000 mg/l and with a Na/TC ratio of about 40%. They required that this be produced by recycling of treated waste water from HTDS ETP and Cooling Tower blowdown from CT4. These effluents are rich in TDS, TSS, TOC, ammonical nitrogen, oil & grease etc with potentially high variation in critical parameters. In a conventional Reverse Osmosis membrane system such effluents lead to recurrent fouling due to biological and organic compounds, resulting in frequent down-time and subsequent deterioration in treated water quality, quantity, overall production time and membrane life.

Scope of Service

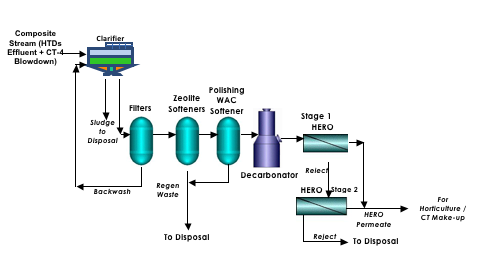

For Reliance, Aquatech designed a system based on HERO™ (High Efficiency Reverse Osmosis) technology. HERO™ is a patented process, most suited for applications where feed water is high in both organic and inorganic foulants. The operating environment of the HERO™ system totally eliminates possibility of biological growth. It is also resistant to fouling occurring because of organics and oil & grease in the membranes, resulting in lower down time of the system for cleaning operations. Membrane system recoveries are comparatively high in the range of 90%+, making this choice high in productivity as well as reliability. At RIL’s Jamnagar refinery, 95 m³/hr of HTDS effluent along with 40 m³/hr of CT-4 blowdown is passed through the HERO™ plant for reduction of dissolved solids, followed by remineralization to balance the Sodium to total cation ratio, before being used for horticulture. Aquatech supplied the plant on a BOOT model, and has now been operating it successfully for the last 3 years.

Design Water Analysis

Process Flow Diagram