Environmental quality remains a high priority in the power industry. These quality requirements result in the advancement of treatment techniques to provide plant discharge air and water to be minimized by reuse or of a quality that is either equal to or higher in purity of the influents.

The Facility

The Brindisi Sud Power Plant is equipped with four coalfired units each of 660 Mwe capacities. These units normally fire imported coal with < 1% sulphur. The flue gases are treated sequentially by SCR-DeNOx with ammonia as reagent, high efficiency ESP to remove fly ash and wet limestone gypsum forced oxidation DeSOx. Each unit is equipped with 2 x 50% DeSOx lines each with a prescrubber for final dedusting and gas saturation and an absorber. The blow down from both prescrubber and absorber along with other wastewaters are sent to a wastewater treatment plant. In the first stage lime and sodium sulfide are added to remove metals. In the second stage ferric chloride is added to remove suspended solids and in the third stage, hydrogen peroxide is added to remove oxidizing agents. The prescrubbers are fed with seawater and at the WWTP; the brine was treated and discharged into the Adreatic Sea.

The Problem

Wastewaters from the Flu Gas Desulfurization (FGD) treatment plant can no longer be discharged into the sea due to tough Italian and EU environmental regulations. To overcome this major environmental problem, ENEL decided to feed the prescrubbers with fresh and recirculated waters and install the Zero Liquid Discharge (ZLD) plant. This is so that no industrial wastewater discharge is allowed by the entire power plant.

The Solution

To overcome the challenge, ENEL selected the Softening – Evaporation – Crystallization (SEC) process to treat the wastewaters and reuse/conserve fresh waters. Aquatech supplied, installed, and commissioned the ZLD plant as an EPC contractor with local associates. The SEC plant is comprised of 2 x 50% softener clarifiers (calcium reduction by soda ash dosing), 2 x 50% falling film type brine concentrators (each equipped with two vapor compressors operating in series), a 1 x 100% crystallizer (equipped with thermocompressors) and 2 x 50% belt filter presses. The plant also includes several chemical dosing systems, storage tanks, pumping systems, electrical works (MCC, cable trays, cabling etc), and controls and instrumentation. The ZLD plant is a fully integrated automated system. The brine concentrators operate in seeded slurry mode. Each brine concentrator is equipped with an external mist eliminator for ease in maintenance. The crystallizer operates in a forced circulation method. The industrial grade soft water and high purity distillate produced in the system will be used in the main power plant.

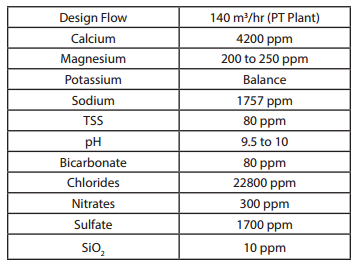

Design FGD Wastewater Analysis

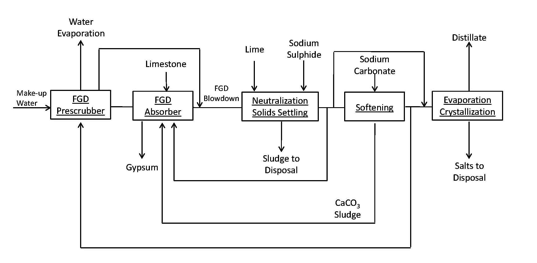

Process Flow Diagram