The Facility

A specialty metals facility located in Euclid, Ohio rolls, forms, cuts and presses specialty metals for the aircraft and aerospace, auto and electrical industries. This plant specializes in high value molybdenum and tungsten, as well as copper parts.

Project Overview

As a result of the metal rinsing processes, the facility discharged water into the local sewer system. Eventually, the Environmental Protection Agency declared that the wastewater could no longer be discharged because the wastewater contained heavy metals at concentrations exceeding new NPDES permit levels.

Scope of Service

Aquatech supplied a Four-Effect Zero Liquid Discharge System. The energy efficient system processes 14 gpm of rinse water and produces approximately 25 lb/hr of solid waste. About 99% of the original wastewater is recovered as high quality water containing less than 10 ppm of total solids, which is recycled and reused in the plant or discharged. A licensed waste contractor was going to be used to dispose of the solid waste offsite in a landfill. The facility owner, however, located a reclaimer company that pays for solid waste and then reclaims the valuable metals.

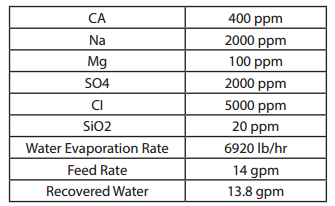

Design Water Analysis