The Facility

The Bajio Power Project is a 600 MW combined cycle project owned by Energía Azteca, a Mexican project company jointly owned by InterGen and American Electric Power. The build, own and operate facility is in commercial operation near the municipality of San Luis de la Paz in the state of Guanajuato, approximately 160 miles from Mexico City.

Project Overview

In 1999, Energía Azteca won the open bidding tendered by Mexico’s national electric utility, the Comisión Federal de Electricidad (CFE), to build Bajío in response to the increasing need for electric power required to support economic growth in Mexico’s central and northern regions. Bajio was built by Bechtel Power under a turnkey contract. There are limited water resources in this arid area. Ground water is not permitted for industrial and power generation purposes. The only supply for boiler feed is silica laden secondary treated sewage gray water. Because of limited supply and discharge restrictions, a high- recovery reliable solution was required.

Scope of Service

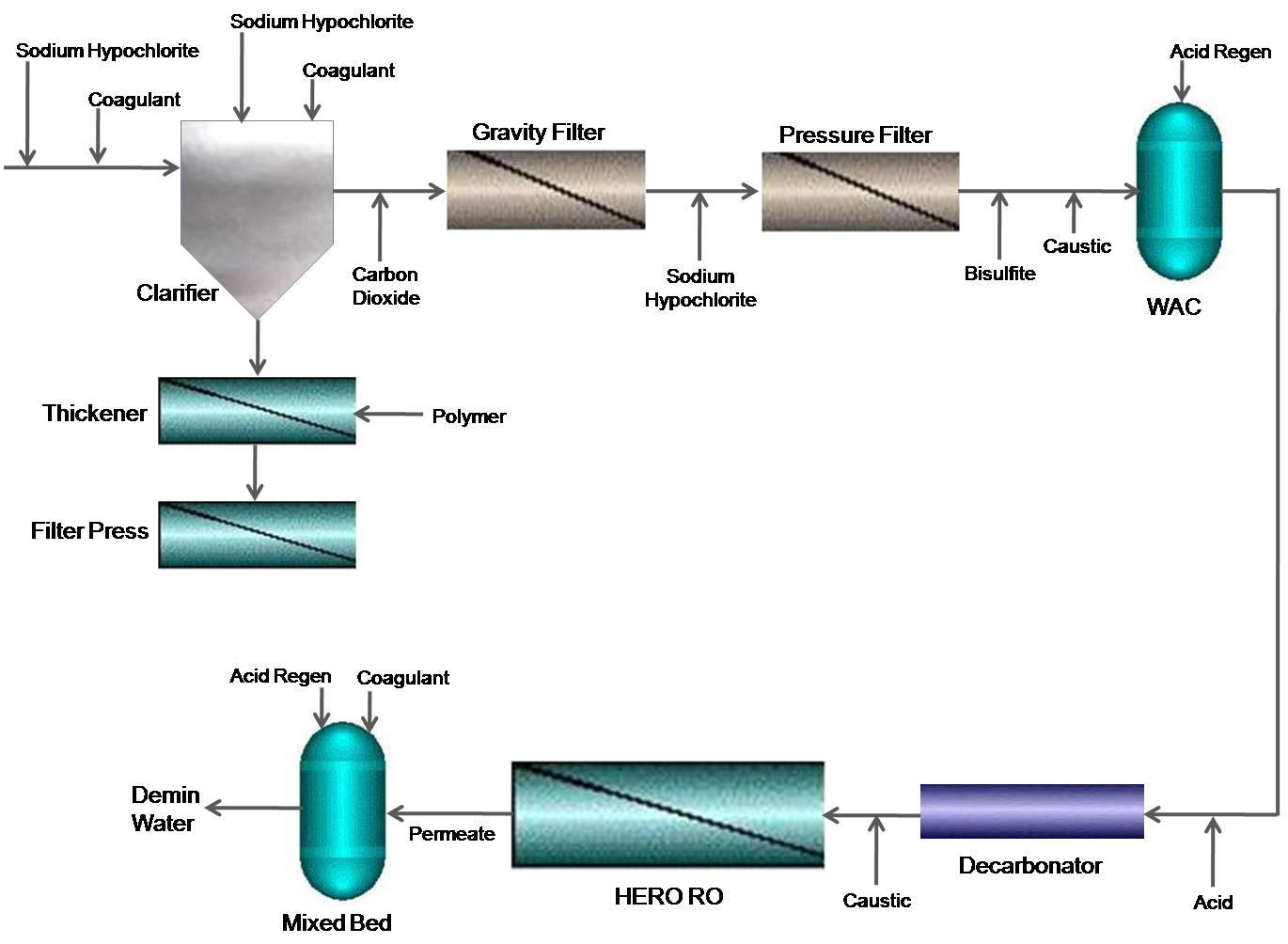

The solution was a treatment plant designed, built and commissioned by Aquatech International Corporation to produce demineralized water for power plant use. It is composed of a pretreatment section and a demineralization section, which is composed of HERO™ pretreatment and HERO™ parts.

The pretreatment consists of clarification and two-stage filtration. More specifically, it consists of a gray water receiving sump and pump facility, a solids contact clarifier, gravity dual media filter, clear well & pressure filter feed pumps, pressure dual media filters, a filtered water tank, backwash pumps and an air scour blower. The pretreatment also includes the sludge handling facilities comprised of sludge transfer air diaphragm pumps, a sludge thickener and a plate and frame filter press. In addition, various chemical dosing systems like sodium hypochlorite, caustic, coagulant (FeCl3), coagulant aid, thickener aid and carbon dioxide also form part of the pretreatment section.

The demineralization section is comprised of filtered water pumps, weak acid cation exchanger units, a decarbonator tower with a catch tank, HERO™ feed pumps, cartridge filters, HERO™ booster pumps, HERO™ units, a permeate tank, mixed bed feed pumps and mixed bed exchanger units. A unique reject stream inclined plate clarifier is used for silica laden sludge thickening.

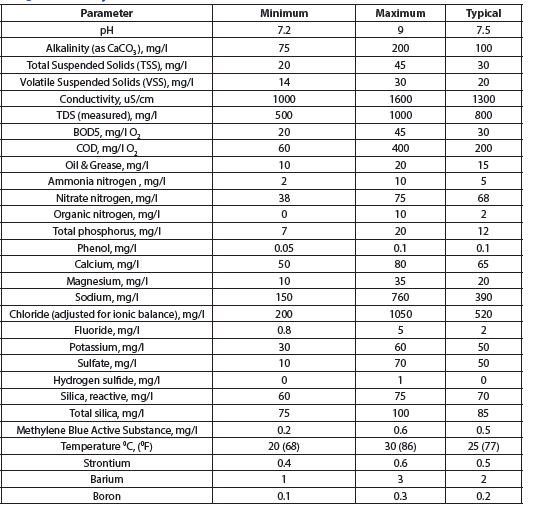

Design Water Analysis

Process Flow Diagram