The Facility

Husky Energy is a Canadian-based energy and energy-related company headquartered in Calgary, Alberta. Husky’s operations can be categorized into three distinct business segments: Upstream, Midstream and Refined Products. The Oil Sands (Upstream Segment) of northern Alberta are one of Husky’s long-term growth areas. Husky has more than 425,000 acres in the Athabasca, Cold Lake and Peace River areas that contain over 33.5 billion barrels of bitumen in place.

Project Overview

Construction on the Tucker Thermal Oil Sands Project began in the fall of 2004. The Tucker Project, which is estimated to have a 35 year project life and peak production of more than 30,000 barrels per day, is anticipated to be commissioned and producing oil by the end of 2006. Husky will use steam assisted gravity drainage (SAGD) technology to recover bitumen at Tucker. A key advantage of the Tucker thermal project is its proximity to Husky’s transmission pipeline system, which can transport diluted bitumen to the Company’s heavy oil upgrader at Lloydminster, Saskatchewan, to be processed into premium synthetic crude. Husky awarded a contract to the 50/50 joint venture partnership between SNC-Lavalin and PCL for the project’s Central Plant facilities. Aquatech received the water treatment order from SNC Lavalin.

Scope of Service

Water requirements for steam generation will come from non-potable salient water sources plus recycled produced water which is separated from the produced bitumen. Over 90% of the project’s produced water will be recycled. Only minor volumes of fresh groundwater will be required for domestic uses at the central plant site which will minimize groundwater impacts.

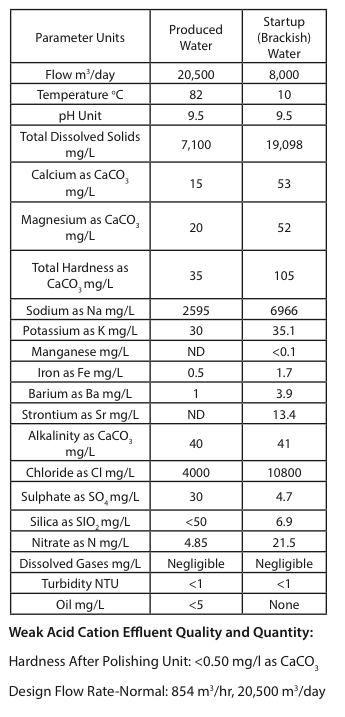

Aquatech International Corporation has supplied three 33% Primary and three 33% Polishing Weak Acid Cation (WAC) units to treat a total 854 m³/hr of produced water from the After Filter units. Each WAC unit is designed to treat a normal flow rate of 285 m³/hr. One WAC will be the lead unit and the other WAC will act as lag unit during normal operation. When the lead unit goes to regeneration, the lag unit will operate as lead, so any of one of the units can be used as lead or lag.

The WAC units operate in sodium form and remove hardness causing calcium and magnesium ions from the feed produced water and provide water with less than 0.5 PPM as CaCO3 hardness. The WAC units are downstream of the Warm Lime Softener & After Filters and they form part of a major process step in produced water treatment. When the unit exceeds the set flow throughput or hardness value, the unit shall be taken offline for regeneration. Acid regeneration followed by caustic regeneration is carried out to regenerate the WAC resin and bring back the resin to regenerated sodium form. There are six- (6) 3960 mm diameter x 3048 mm straight shell WAC units– each with skid mounted, pre-wired and pre-assembled manifold piping. Treated softened water for backwashing and dilute acid and caustic for regeneration shall be provided by others near the face piping skid of each WAC unit at approximately 50 psig.

Weak Acid Cation Feed Water Analysis