The Facility

The AK Steel Middletown Works plates zinc nickel alloy onto steel strips. They started their first plating line in 1991 and expanded from twenty-one to thirty-two cells in 1995.

Project Overview

In order to maximize line speed and thus production, the strip needed to be rinsed immediately after plating. The rinse water was diluted electrolyte solution and a portion of the electrolyte had to be disposed to maintain the required electrolytic balance in the solution. The excess diluted electrolyte could not be discharged locally, so it had to be trucked away. AK Steel needed a system to remove the excess water to allow all of the electrolyte to be recycled. They wanted an energy efficient system that was easy to operate with minimal attention. The system was also required to eliminate the high disposal costs.

Scope of Service

Aquatech worked closely with AK Steel to design the best possible system for their needs. After a thorough evaluation of all possible evaporator types and energy sources, Aquatech proposed a vertical-tube falling-film evaporator with thermal vapor compression. The system features provides the following benefits:

- Low steam and cooling water consumption to minimize operating costs.

- Automatic “one-button” start-up, shut-down, and operation to virtually eliminate operator time.

- High reliability with simple components to reduce maintenance requirements.

- Fast equipment delivery and ease of installation to eliminate the electrolyte disposal costs.

- Provide high purity distillate at less than five mg/l TDS to be used for plating rinsewater without further treatment.

Aquatech delivered the system equipment in five months. Based on the detailed drawings provided, the system was installed in less than two months. Commissioning followed and the system was operating and passed performance test in less than eight months from order placement

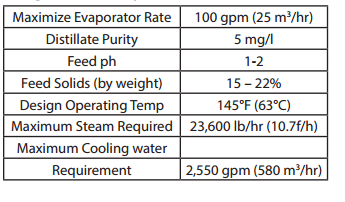

Design Water Analysis

Process Flow Diagram