Aging infrastructure and increasing demand for high capacity biological water treatment have created a need for more efficient, compact and affordable solutions. Integrated treatment systems must be easy to operate and install while minimizing capital expenditure. These new systems must also be capable of addressing frequent changes in feed water. A mobile, packaged solution is thus key to enabling companies to manage their wastewater with the most efficient technology at the lowest cost.

• Various packaged models are available to accommodate treatment needs across a variety of industries and feed water conditions.

• Packages are capable of being operated in series or parallel modes for flexibility in effluent quality and flow rate, respectively. Service Features

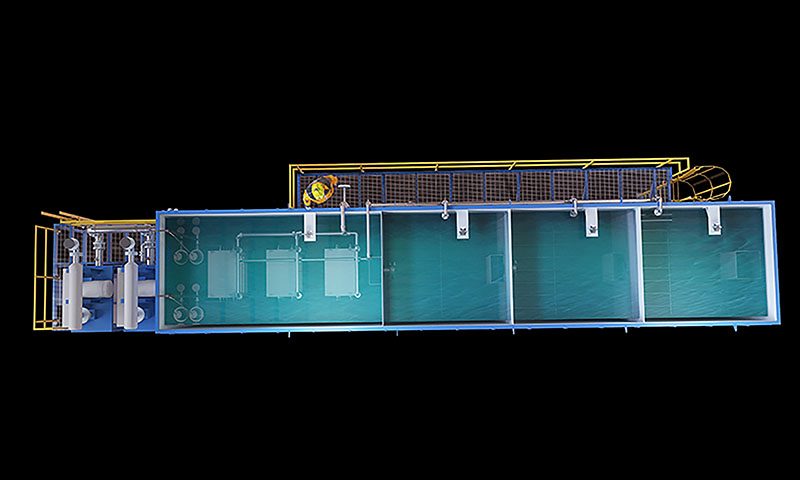

• All process components are included within a single skid to simplify transport, layout and operation. Within our 53’ length scope, we include aeration blowers, feed pumps, PLC and controls.

• Quick assembly and delivery is guaranteed with our unique MBR design

.

• One BioMOD™ MBR package can be used for multiple projects and occupy minimal footprint. For clients with these types of needs, we can easily transport the packaged system with the use of a standard freight truck.

• By minimizing the client expenditure for production, installation, commissioning, and operation, the BioMOD™ MBR provides a highly economical solution.

• Simplified operation and service through automated systems, which are able to regulate frequency of reverse diffusion cleaning. Additionally, service needs can be easily handled with Aquatech’s support.

• Employs EnviQ, a patented flat sheet PVDF mem brane with ultrafiltration quality permeate, allowing for the system to be directly followed by RO

• Can handle MLSS concentrations 3,000-15,000 mg/L

• Low downtime due to reverse diffusion cleaning method instead of backwash

• 20 – 60 GPM capacity MBR plant which comes fully preassembled

• Effluent quality suitable for further recycling and reuse

• Membrane can operate even after damage due to auto-cure capability

• Low frequency of chemical cleaning due to elimination of dead pockets, which cause biofouling in competing products

• Low energy consumption

• Simplified transportation, installation and operation

• Enhanced automation enabling ease of operation and optimum efficiency

• Limited infrastructure construction or modification required

• Consistent product quality regardless of feed load variance

• Extensive experience innovating in membrane technology

• Product capacity accurately determined based on client specifications

• User-friendly operation and support

• Fast delivery and installation

• Optional integration with direct solar energy