In 2014, the Federal Electricity and Water Authority of the United Arab Emirates, in EPC partnership with Aquatech International, completed the construction and commissioning of a desalination plant at Ghalilah in the Emirate of Ras Al Khaimah that today provides vital fresh water to the distribution network of FEWA. The desalination plant produces 15 million Imperial gallons of fresh, potable water each day, water that meets World Health Organization standards. As FEWA’s largest desalination plant to date, the facility will help conserve ground water and bring the UAE closer to its goal of decreasing ground water dependence by 90% in the next two years

The Facility

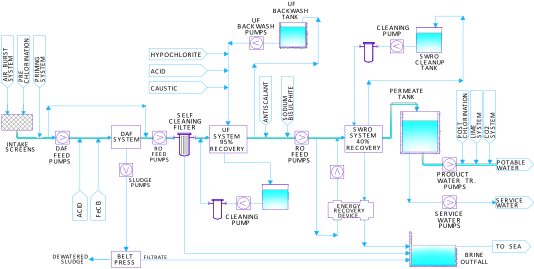

Using reverse osmosis, or RO, technology, the plant treats seawater with salinity levels as high as 42,000 parts per million to produce fresh water suitable for drinking, with a product salinity of less than 500 parts per million. The facility is one of the large-scale desalination plants in the Gulf to utilize RO technology. An energy efficient membrane process, RO has been widely used in other parts of the world. It is now gaining traction in the Gulf region, where thermal desalination technologies have traditionally been employed. Aquatech supplied a complete integrated facility on an EPC basis, which included the seawater intake, dissolved air flotation technology to protect from seasonal red tides, ultrafiltration, reverse osmosis, and post treatment. A sophisticated DCS System for performance enhancement and data monitoring was also supplied, ensuring that FEWA is equipped with the desalination industry’s latest technologies and a world-class facility.

The system consists of the following:

- Seawater intake screening

- Seawater intake pipe

- Shoreline protection

- Intake chlorination system

- Pump house concrete structure

- DAF system

- Ultrafiltration skids

- High pressure pumps with

- Energy recovery device

- Seawater reverse osmosis skids

- Reminaralisation system

- Post chlorination unit

- DCS system

- Transformers and switch gears

- Electromechanical Installation

- All the civil works related to the plant

The Process

The desalination process starts by drawing seawater from the Gulf that enters the plant through intake pumps. The seawater is then pumped to state-of-the-art ultrafiltration units. Ultrafiltration membranes provide effective pretreatment prior to the RO membrane stage, thus increasing the reliability and longevity of the system.

The pre-treated water is then pumped under high pressure to the reverse osmosis units. In these units, water molecules pass through the RO membranes while salts are rejected and end up in a waste stream that is safely discharged. The product is the fresh water obtained through the RO process.

| INLET PARAMETERS | OUTLET PARAMETRS | ||||

| pH | : | 8.46 | pH | : | 7.5 – 8.5 |

| Turbidity, NTU | : | 30-35 | TDS, mg/l | : | <= 500 |

| TDS, mg/l | : | 42,000 | Boron, ppm | : | <= 2.0 |

| Calcium, ppm | : | 470 | Chlorides | : | <=200.0 |

| Magnesium, ppm | : | 1,500 | |||

| Sodium, ppm | : | 12,500 | |||

| Potassium | : | 390 | |||

| Bicarbonate, ppm | : | 98.57 | |||

| Carbonates, ppm | : | 29.96 | |||

| Chloride, ppm | : | 22,277 | |||

| Sulfate, ppm | : | 3,100 | |||

| Boron, ppm | : | 4.1 | |||

| Total Hardness, ppm | : | 7,350 | |||

| Temperature, °C | : | 18 – 36 | |||

| Design Temperature, °C | : | 22 | |||

Process Flow Diagram