Innovative engineering design to optimizing extremely limited space provides long lasting success for Mumbai International Airport Ltd. (MIAL) wastewater treatment plant.

Project Overview

Mumbai International Airport Pvt. Ltd., or MIAL – a joint venture between a GVK-led consortium and the Airports Authority of India – was awarded the mandate to modernize and upgrade the Chhatrapati Shivaji International Airport – known as CSIA – to a world-class airport.

As a part of CSIA’s massive expansion plan, a 10 million liters per day (MLD) wastewater recycle project was contracted to cater to the growing requirements of the expanded airport.

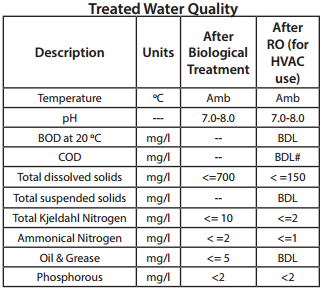

Due to increasingly strict environmental regulations, the treatment of raw sewage wastewater is required before it is allowed to flow into the natural ecological system. As the airport has a lack of fresh water availability for its requirements, it needs to recycle and reuse the treated sewage water for its operations, such as toilet flushing, horticulture, and HVAC cooling makeup water. Approximately 4 MLD of the treated sewage water is used as HVAC cooling water, 3 MLD is used for flushing, and 3 MLD is used for horticultural and operational purposes.

Aquatech was awarded an EPC contract to supply a 10 MLD sewage treatment and recycle system on a complete turnkey basis for the new airport terminal. MIAL chose Aquatech due to its long and successful record in providing treatment systems for a variety of purposes. The MIAL wastewater treatment project had some key design and water quality challenges that Aquatech successfully overcame through an innovative process and system design.

Challenge

This project required extensive design ingenuity, as the space allotted for the plant was unusually shaped and smaller than what is suitable for a plant of this capacity.

Normally, a plant of this size would require at least 5000 square meters. However, Aquatech was allotted a plot of land half that size, 2600 square meters, to construct the MIAL wastewater plant. Instead of the normal square design, the plot provided is triangular in shape and completely surrounded by utility buildings and an adjacent river, allowing no space for potential expansion. These tight constraints were put into place to allow space for all components of Mumbai’s airport expansion project without disrupting the airport’s existing daily operation.

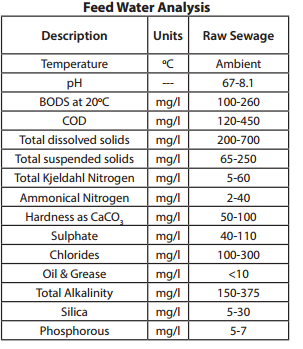

Additionally, the incoming water to the plant was variable in its quality. Since the wastewater entering the system is mainly from the airport and not usual city sewage, it was expected to be rich in Total Kjehldahl Nitrogen (TKN).

It also was expected to have a high turbidity and silt density index (SDI). Aquatech decided that the best way to combat the water quality challenges was to configure a combined biological

Aquatech Solution

Aquatech’s engineers designed an innovative wastewater treatment system based on the limited plot size allotted. The MIAL plant is an integration of many technologies – a combination of biological treatment followed by advanced tertiary treatment based on UF and RO processes.

The primary treatment consists of coarse and fine bar screens followed by a grit chamber. The secondary treatment consists of an AECOM Cyclic Activated Sludge System (CASSTM) sequencing batch reactor (SBR) biological treatment technology followed by disinfection. The tertiary treatment includes a QUA® ultrafiltration (UF) pretreatment system followed by a reverse osmosis (RO) system, after which the water is reused and distributed for the airport’s various purposes.

Aquatech’s engineering team devised a circular design that took advantage of the basin shape to fit two SBR basins into the triangular plot. However, this design left a very small amount of space to place the recycle system in.

To address this issue, the Aquatech team placed the chlorine contact, feed, and permeate tanks (eight total) in a vertical configuration with the pressure sand filters, UF system, and RO system placed on top of the tanks. A typical wastewater treatment system calls for all of these components to be constructed in a series, but this configuration was not possible in this plant.

The vertical engineering design not only allowed the MIAL wastewater plant to adhere to the strict space requirements, but it also provided a more economical and optimized solution that would successfully provide high quality water over many years.

The site is fully operational and performing well in auto mode. The sewage wastewater treatment plant has been in operation for more than a year and is successful due to its innovative design and integration of optimized and advanced treatment technologies.

BIOLOGICAL TREATMENT: RELIABLE SBR WITH INNOVATIVE DESIGN

Aquatech chose AECOM CASSTM, an advanced SBR technology to combat the plant’s biological treatment needs. However, this treatment step proved to be challenging to design in as a result of the limited space to work within. To solve this problem, Aquatech selected an SBR system that operates both biological treatment and solid-liquid separation in a single reactor basin that alternates operation modes, eliminating the need for final clarifiers and high return activated sludge capacity. This SBR system is designed to minimize the plant footprint while optimizing process performance and energy efficiency.

EFFECTIVE RO PRETREATMENT: COMBATS VARIABLE FEED WATER

Aquatech evaluated both UF and conventional media filtration for pretreatment to MIAL’s RO system. Since the water feeding the pretreatment system was sewage wastewater, the pretreatment step needed to be designed to handle variable water qualities and extremely high turbidity levels. The primary goal of the RO pretreatment system was to reduce the silt density index (SDI) and turbidity of the water feeding the RO to a point where RO cleaning would be minimized. A UF system followed by an RO system was integrated into the system to provide a complete treatment solution.

Design Water Analysis

Process Flow Diagram