The Facility

The Magnolia Power Project is utilizing state-of-the-art combined-cycle electric generation technology and was built on four acres of Burbank Water and Power’s (BWP) generation station complex adjacent to Magnolia Boulevard in Burbank. Aker Kvaerner served as the Magnolia Power Project engineering, equipment procurement and construction contractor, and has been conducting engineering tasks since September 2002. On June 10, 2003, the mayors and utility officials of the six participating cities joined together with SCPPA officials for a Magnolia Power Project ground breaking ceremony to commemorate the start of on-site work. As part of the ceremony, a dwarf magnolia tree was planted at the entrance to what will become the project’s control and service building. The 310-megawatt (MW) power plant will serve as locally operated power generation for the cities of Burbank, Anaheim, Glendale, Pasadena, Cerritos and Colton.

Project Overview

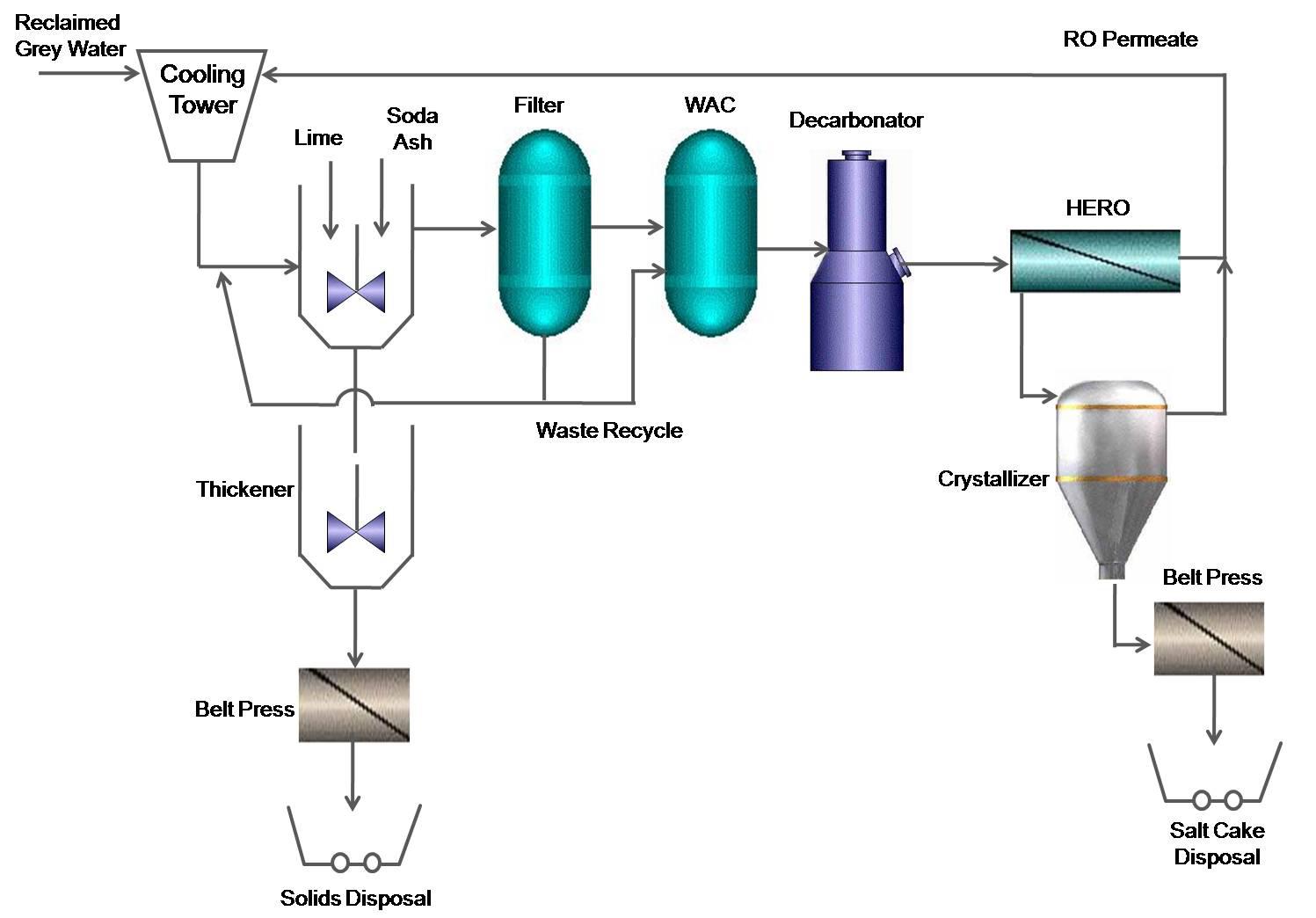

In order to expedite the CEC licensing process and ensure electrical generation availability by mid-2005, the Magnolia Power Project selected a “zero liquid discharge” option for the power plant’s reclaimed cooling water system. The Zero Liquid Discharge (ZLD) equipment allows the city to recycle/reuse the wastewater and adopt a policy of water conservation.

The Magnolia Power Project started their ZLD system evaluation process by looking at the traditional ZLD methods that use brine concentrators which consume electrical energy to evaporate the waste water. The evaporated wastewater is recovered and recycled back for power plant operation. The solids left behind in this process are converted to sludge and disposed offsite as landfill. The brine concentrators consume huge amounts of electrical energy, even while they are in standby mode, i.e. not generating any output.

Scope of Service

After reviewing the available technologies, the City of Burbank’s Magnolia project selected the HERO™/ Crystallizer process on the following basis:

-Significant reduction in Power Consumption: The HERO™(high efficiency reverse osmosis) process replaces the brine concentrator and recovers the water using reverse osmosis membranes. By avoiding the need to evaporate the water in this stage of the treatment process, the HERO™ process significantly reduces the power consumption. For the City of Burbank, power thus saved is power generated.

-Start and stop operation: The operating profile of the Magnolia Power Project will cause the ZLD equipment to operate in a start and stop operation. The traditional Brine Concentrators operate on the heat cycle and achieve their best efficiency when operating continuously. Short term in-operation of the ZLD system requires these units to be maintained in hot standby condition which consumes valuable electrical power while generating little or no output. Compared to this, a HERO™ based system has start and stop capability and can be operated only when required. Besides easing operations, this further helps reduce power consumption.

-Visual Impairment: The project is located within the city limits and hence visual impact was a big consideration.

Traditional ZLD methods using Brine Concentrators would have required tall structures exceeding 100 feet in height to be installed at the site. Magnolia project gave a lot of consideration to minimizing the visual impact and by using the HERO™ process lowered the overall height of the system to less than 50 feet.

-Space Constraints and Delivery of Equipment: Being located within the city limits, the project faced additional constraints of limited available space. To further aid the visual impact, the ZLD equipment was located at the back of the power plant. This coupled with limited laydown area for equipment as it arrived from the manufacturers required that this equipment be delivered on an expedited schedule. The HERO™ system, compared to a Brine Concentrator, saved the project approximately 12 weeks on the overall delivery. This helped the project lower its installation costs by setting the equipment in place as it arrived from Aquatech International Corporation.

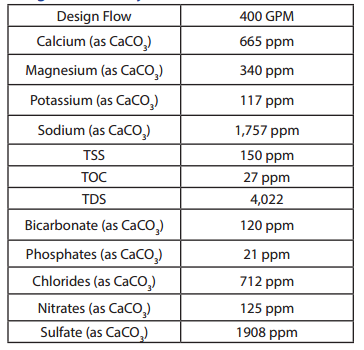

Design Water Analysis