The Facility

The Roseville Energy Park (REP) will be a natural gas-fired, combined-cycle electrical generating facility. The project, planned for a 12-acre site, will be owned by the city and will use state-of-the-art equipment to locally generate about 60 percent of Roseville’s electricity needs. The Roseville

Energy Park will use recycled wastewater from the nearby Pleasant Grove Wastewater Treatment Plant as its source of cooling water during operation. A zero liquid discharge (ZLD) system will be used to recover process wastewater and generate sludge for offsites disposal.

Project Overview

The California Energy Commission’s Energy Facility Licensing Process required Roseville Energy Park to be a ZLD site and use alternative sources of water for their cooling discharge water needs. To provide savings in capital cost, operating cost and more operational flexibility to handle fluctuating water chemistry and flows, Aquatech is supplying a HERO™ membrane process and 2 x 50% Crystallizers.

Scope of Service

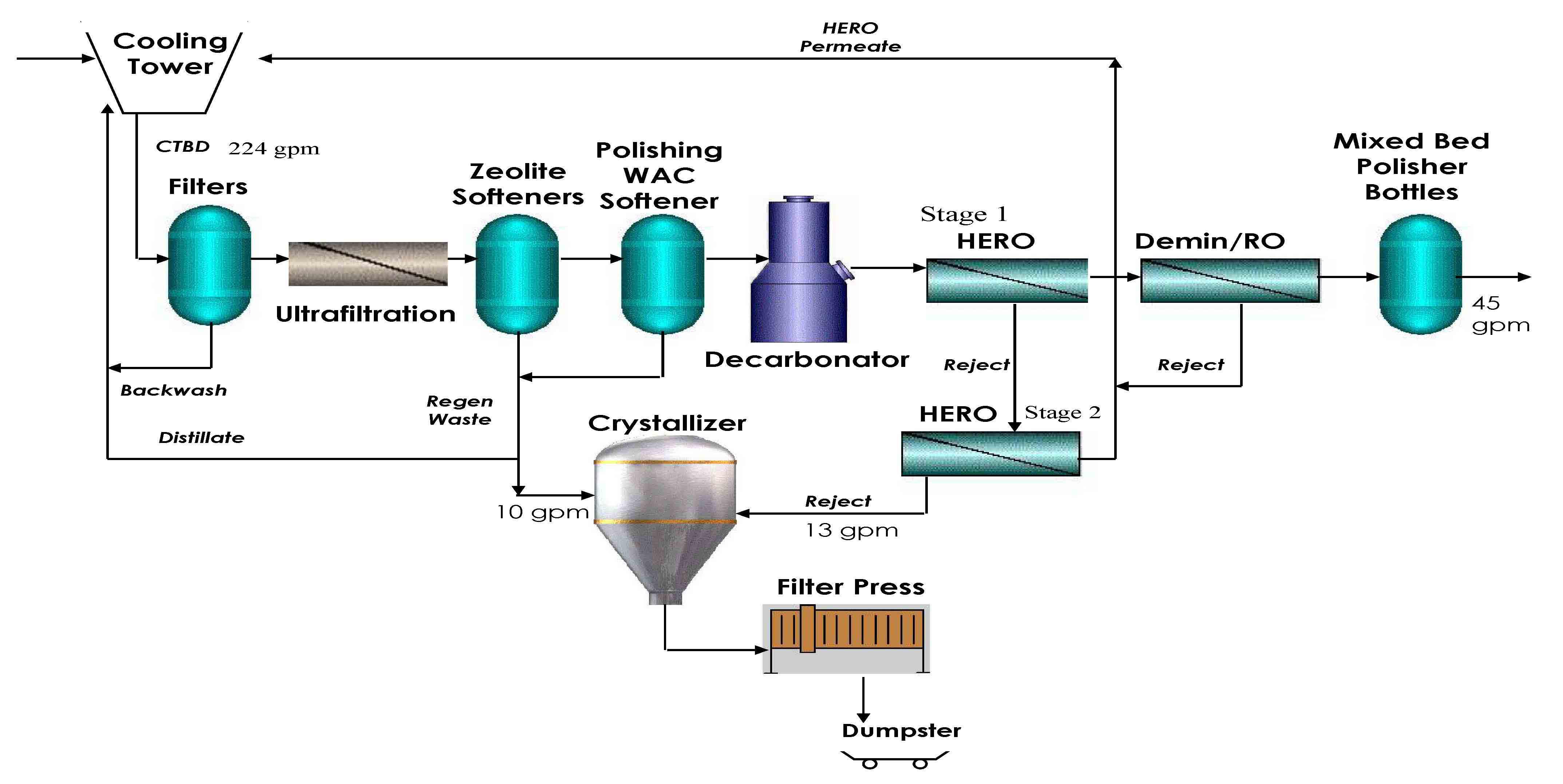

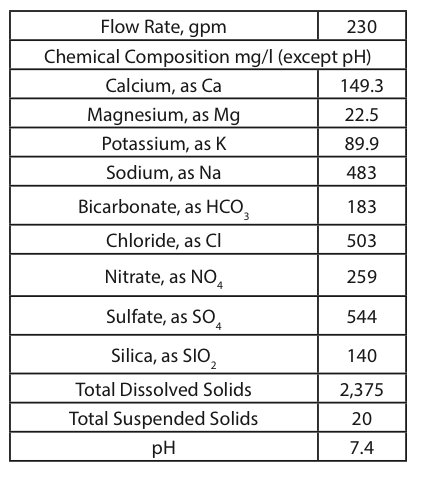

The HERO™ system, designed to handle 230 gpm of cooling tower blowdown, is capable of excellent turndown. In addition, it can be turned off and on virtually instantaneously, regardless of the length of time between shutdown and startup, without any special procedures. The HERO™ system will also produce demineralized water without any separate make-up water system. The HERO™ System consists of 3 x 50% Filtration units followed by a Softening System in 2 x 100% configuration followed by a Decarbonator and pH adjustment of the RO feed. The RO is furnished in 2 x 100% units. The softener units remove all the scale-forming ions such as calcium, magnesium, barium, iron, aluminum, etc., and caustic dosing takes advantage of very high silica solubility at elevated pH. As a result, the HERO™ unit operation is trouble-free, with minimal downtime required for regular cleaning due to scaling.

At the design feed rate of 230 gpm, the HERO™ system will reduce the wastewater quantity to 23 gpm. Part of the permeate from the HERO™ system will be processed to produce the demineralized water meeting the specified quality. The HERO™ reject along with the softener regeneration waste shall be processed in 2 x 50% crystallizer units.

Two x 50% Crystallizers will be used to concentrate the 23 gpm of HERO™ blowdown and primary softener regeneration wastewater, and these crystallizers are integrated with automatic belt press filter.

Design CTBD Analysis

Process Flow Diagram