The Facility

Gilberton Power Company, John B. Rich Memorial Power Station, located in Frackville, PA began operations in mid-1988. This Co-Generation plant has been generating over 590 million-kilowatt hours of electricity per year for sale to Pennsylvania Power & Light. Gilberton Power Company, which was the first Co-Generation plant in this area, utilizes two pyro power circulating fluidized bed combustors (CFB’s). The 80- megawatt plant burns almost 425,000 tons of processed anthracite waste (culm) per year. Waste Management and Processors, Inc. (WMPI) reclaim this fuel from an estimated 1,700,000 tons of waste material and dispose of approximately 156,000 tons of ash per year under a Pennsylvania Department of Environmental Resources permit. The CFB boilers burn the processed fuel in a low temperature staged combustor utilizing limestone injection to capture sulfur and assure efficient combustion at the lowest possible emissions levels. The plant complex includes a culm reprocessing plant designed and built by J & R Engineering Corporation to ensure delivery of consistent quality low ash fuel to the boilers.

Project Overview

The Gilberton Power Company utilizes make-up water at a rate of 1100 gpm. The source of this water is drawn from nearby mine pools and deep wells. These pools and wells provided the company the benefits of a steady supply of large volumes of local accessible source water. However, treatment was required before the source water could be utilized. The source water has an undesired level of iron which required treatment before use. This treatment is achieved with equipment and technology supplied by Aquatech. The Aquatech treatment reduces the iron levels, which cause the orange color of AMD shown in Figure 1, from 46 ppm to 0.05 ppm.

Local Project Benefits

The PA DEP is responsible for addressing the acid mine drainage and discharging it into the Mahanoy Creek. From April 2010 to May 2011, the PA DEP operated on an average of 11 hours per day pumping 3000-5000 gpm of Acid Mine Drainage (AMD) into the Mahanoy Creek. This volume is 3.3 MGD of AMD disposed to the creek. As a result of the Aquatech water treatment process operating at the Gilberton Power Company, the plant is able to utilize 1.2 MGD of AMD for the power plant operations and thereby avoid 1.2 MGD of the total AMD volume being discharged to the Mahanoy Creek. In addition, the plant utilization of the AMD has no cost to the taxpayer, benefits their community by providing the generated power, and reduces the impact of the AMD upon the local environment, specifically the Mahanoy Creek and adjacent waterways and vegetation.

Pennsylvania Benefits

Drainage from thousands of abandoned coal mines has contaminated more than 3,000 miles of streams and associated ground waters in Pennsylvania and is the most extensive water-pollution problem affecting the four major river basins in Pennsylvania. While the state spends about $19 million annually on abandoned mine reclamation, this modest effort is dwarfed by the magnitude of the environmental problem. To date, relatively few AMD areas have been remediated, because of cost, potential liability and a lack of meaningful economic incentives. Because many current and future Marcellus and Utica Shale wells are in close proximity to AMD areas, there is a unique opportunity to beneficially use these waters for hydraulic stimulation. The Aquatech acid mine drainage treatment applied at the Gilberton Power Plant can be implemented throughout Pennsylvania to condition the water to meet requirements by Marcellus and Utica operators to meet their dynamic requirements for an abundant source water for hydraulic stimulation. The AMD treatment can be implemented in fixed, modular, and mobile treatment offerings and thereby accommodate their local, regional, and state requirements.

Scope of Service

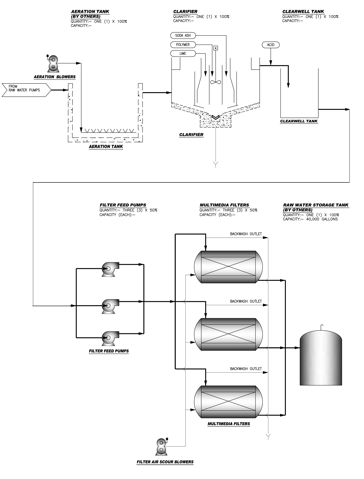

The Aquatech treatment process consists of the following main elements:

1. Filter trays

2. Aeration tower / Premix tank

3. Lime Slurry / pH adjustment

4. Flocculation tank

5. Clarifier

6. Mixed-bed filters

7. Holding tank of cleaned water