The Facility

Tenaska IV Texas Partners cogeneration facility in Cleburne, Texas is a producer of electricity at a combined cycle plant.

Project Overview

Tenaska wanted their Cleburne plant to be a Qualified Facility (QF). To achieve this, they elected to produce distilled water using the steam from the power generating equipment. A distilling plant using reverse osmosis reject as the feed will be used as a steam host and will produce potable water.

Scope of Service

Since the primary goal was to produce distilled water using steam, the evaporator was considered to be a “steam host.” One solution was to use a vertical tube falling film evaporator, but Aquatech chose an alternative approach using our patented Spray-Film® evaporator which used the reverse osmosis plant reject as the feed source to produce distilled water. The design allowed the concentration factors to be kept low to avoid silica and calcium salt scaling. The evaporator operates at a low concentration factor, resulting in a higher distilled water production per each square foot of heat transfer surface. This also reduces scaling and corrosion potential. The plant described is easily installed because most interconnected piping, automatic controls, and electrical wiring are integral parts of the packaged evaporator skids. There are a minimum number of piping and electrical connections required upon installation. The system is easily operated and requires minimum attention by the operator. Installation of the evaporator was March 1996 and commissioning was September 1996.

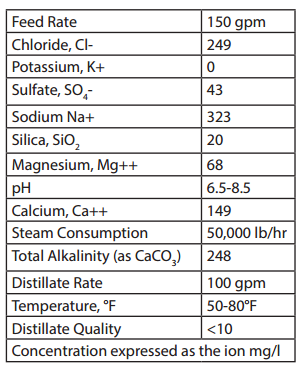

Design Water Analysis