The Facility

Aquatech is supplying the equipment for two (2) 525 gpm seawater distillation systems to Saudi Arabian Oil Company’s Ras Tanura Refinery in Saudi Arabia.

Project Overview

Aquatech was successful in meeting the strict Technical & Delivery requirements. In general the infrastructure was capable of supporting the needs of up to 525 USGPM desalination units.

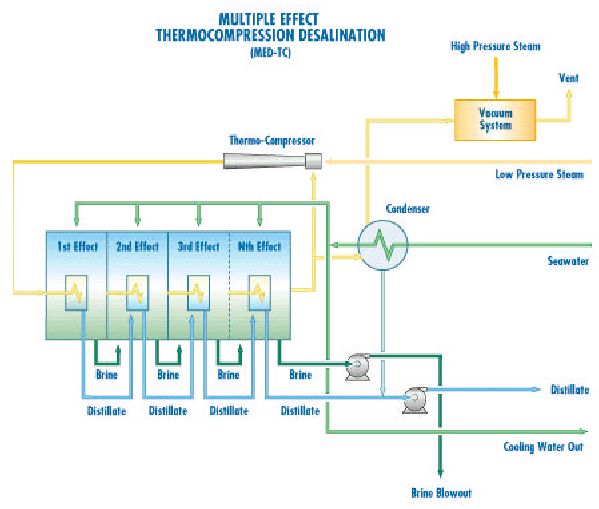

The evaporator is a four effect thermal vapor compression system with the following conditions:

- Seawater temperature range from 48°F to 95°F.

- Seawater TDS 51,000 ppm.

- Distillate (final product from MED) purity 5 ppm TDS.

- Design capacity of 525 USGPM with turndown to 50% of design capacity.

- Operate at a Gain Output Ratio of 6.5 kg of distillate/kg of steam input to the thermo compressor

- The most important feature of Ras Tanura Project is the Superior Metallurgy of Components of MED plant.

- Shell, all 4 effects : UNS S 31254 (SMO 254)

- Shell Internals – tubesheets, spray headers, supports : UNS S 31254 (SMO254)

- MED Tubes: Titanium

- Condensers: Titanium

- Ejectors : UNS S 31254 (SMO 254)

- Valves & Instruments : SMO 254 / SS 317L / Monel etc.

Scope of Service

The Multiple Effect Thermal Vapor Compression Seawater Desalination Plants are designed to meet the following requirements:

• Provide an output of 525 USGPM each

• Operate at a Gain Output Ratio of 6.5 lb of distillate/lb of steam input (to thermo compressor)

• Minimize carryover of solids into the distillate for purity of not more than 5 ppm TDS

Aquatech’s Multiple Effect (MED) Thermal Vapor Compression design is a 4 effect unit which incorporates SPRAY‑FILM® technology, a registered trademark of Aquatech. Aquatech’s MED design is the result of over 25 years of experience in the design, manufacture, start‑up and operation of MED evaporator systems worldwide.

For this system, steam or water vapor condenses inside horizontal tubes. Seawater is sprayed over the outside of the horizontal tubes and acts as a heat sink for the condensing vapor. The latent heat of vaporization transfers from the water vapor through the tube wall to the thin seawater film on the outside of the tubes.

Process Flow Diagram