The Facility

A major industrial Fortune 500 company manufactures armored-tracked vehicles for the U.S. Army. The plant is located in York County, Pennsylvania.

Project Overview

Aluminum and steel assemblies and parts undergo chemical dip and spray treatments before painting. The wastewaters produced by this process were conveyed to a wastewater treatment facility where the wastewaters underwent physical and chemical treatment. The treated effluent was then transferred to the waterway and the excess sludge to the landfill.

Scope of Service

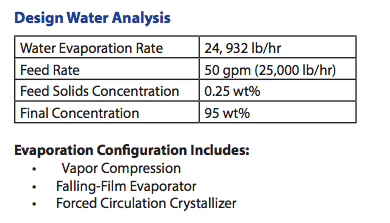

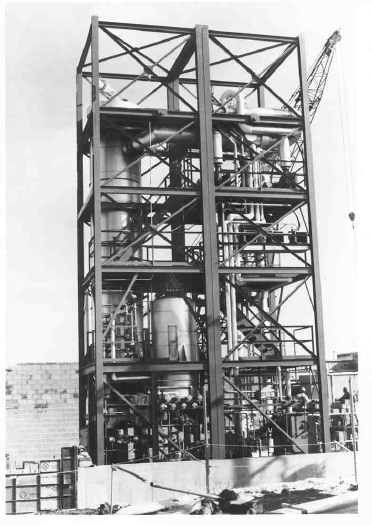

A Vertical tube falling-film evaporator system designed with vapor compression and a forced circulation crystallizer produce a distillate reusable in plant processes. Distillate quality meets all NPDES permit requirements. The system handles various feed rates and feed chemistries and minimizes solid waste requiring landfill disposal. The system is monitored by a programmable logic controller (PLC) that interfaces with the plant’s PLC to control the waste treatment support facilities. The evaporator/crystallizer is completely skid mounted and consists of two skids with integral piping, walkways and stairs. The feed goes to the vapor compression evaporator which concentrates the wastewater to 22wt%. This transfers to the crystallizer to be concentrated to about 45 wt% before being dewatered in the filter press. The salt cake is discharged from the filter press at 80-90 wt% solids. The distillate from the evaporator and crystallizer are#10 ppm TDS and suitable for reuse in the plant. Start-up completed March, 1992. Process 50 gpm (25,000 lb/hr). The stream sepa rates into 24,932 lb/hr os disstillate and 66 lb/hr of handleable solids. Continuous operation. Complies with current discharge limits of the NPDES permit.

Design Water Analysis