The Facility

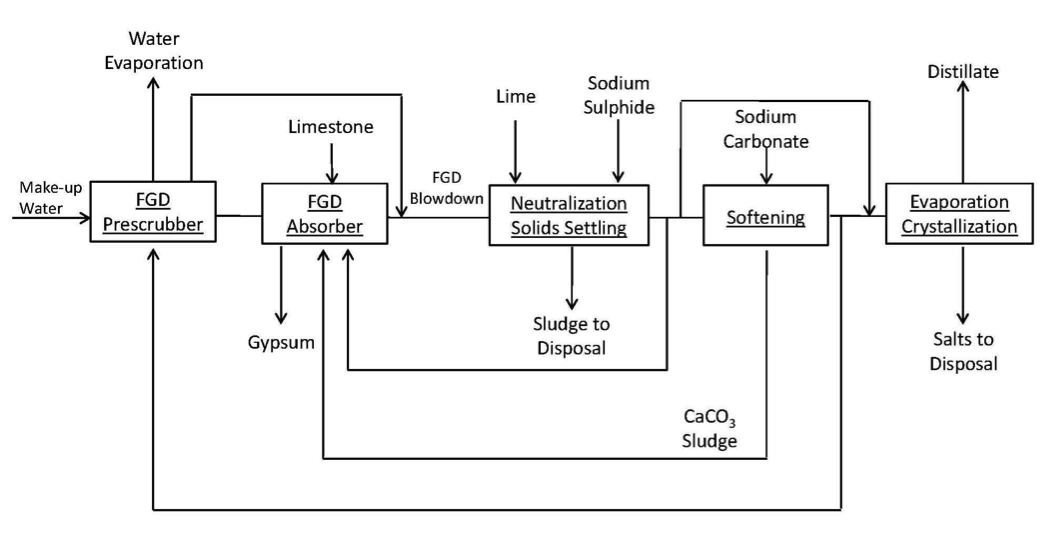

The Fusina Power Plant is equipped with four coal-fired units with a total capacity of 975 MW capacities (1 x 165 MW + 1 x 170 MW + 2 x 320 MW). The Environmental Refurbishment (Flue Gas Desulpharization, (FGD) project includes a new DeSOx system for common for units #1 & 2; two DeNOx systems, one each for unit #1 & 2. Units #3 & 4 are already equipped with DeSOx and DeNOx systems. For units #1 & 2, Industrial grade water is used as FGD make-up. Flue gases in the FGD are treated with limestone in the scrubber. The FGD blow down wastewaters are treated in the dealkalizer clarifier with lime treatment. For units #3 & 4, the flue gases are treated sequentially by SCR-DeNOx with ammonia as reagent, high efficiency ESP to remove fly ash and wet limestone gypsum forced oxidation DeSOx. Each unit is equipped with DeSOx system with a prescrubber for final dedusting and gas saturation and an absorber. The FGD blow down wastewaters along with units #1 & 2 are treated in the dealkalizer clarifier with lime treatment and being discharged into the surface waters.

Project Overview

Wastewaters from FGD treatment plant can no longer be discharged into the sea due to tough Italian and EU environmental regulations. In order to overcome this problem, ENEL decided to install the Zero Liquid Discharge (ZLD) plant so that no industrial wastewater discharges are allowed.

Scope of Service

To overcome the problem, ENEL selected the Softening – Evaporation – Crystallization (SEC) process to treat the wastewaters and reuse/conserve fresh waters. Aquatech supplied, installed, commissioned the ZLD plant as an EPC contractor with local associates. The SEC plant comprises of 2 X 50% Softener Clarifiers (calcium reduction by soda ash dosing), 2 x 50% Falling Film type Brine Concentrators (each equipped Vapor Compressor ), 1 x 100% Crystallizer (equipped with Thermo compressors) and 2 x 50% Belt Filter Presses. The plant also includes several chemical dosing systems, storage tanks, pumping systems, electrical works (MCC, cable trays, cabling etc), controls & instrumentation. The ZLD plant is a fully integrated automated system. The Brine Concentrators operate in seeded slurry mode. Each Brine Concentrator is equipped with internal mist eliminator. The Crystallizer operates in forced circulation method. The industrial grade soft water and high purity distillate produced in the system will be used in the main power plant.

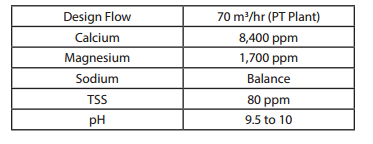

Design FGD Wastewater Analysis