The Facility

Laminex Industries in Gympie, Queensland, Australia is a leading producer of medium density fibreboard-based panel products. Laminex Gympie is a zero wastewater discharge site. Laminex was installing a second plant at their site to expand production capacity. It became apparent that borewater quantity and quality was unpredictable, therefore Laminex decided to recycle wastewater from their existing managed wetlands to produce boiler feedwater.

Project Overview

The majority of the plant’s wastewater is produced in the chipwash and chip preparation operation where steam is used to prepare chips for production. The wastewater goes through a series of treatment steps and aeration ponds before discharging to the wetlands. The goal was to close the loop and convert the wetlands water to boiler feedwater for use in their steam generator. The quality of the water varied considerably and was too high in contaminants to use traditional demineralizer technology.

Scope of Service

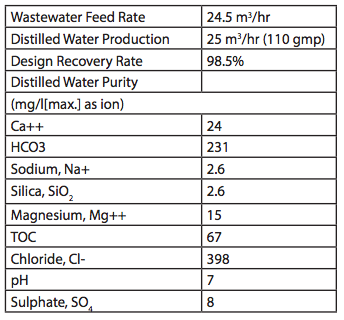

Aquatech supplied a mechanical vapor compression brine concentrator to convert up to 98.5% of the wetlands water into 25m³/hr (110gpm) of boiler feedwater. The residual amount of concentrate remaining can be easily accommodated on site.

The mechanical vapor compression process is highly efficient using only about 400 kW of power and eliminated the need for additional steam generation. The brine concentrator uses seeded slurry technology to minimize scaling due to calcium sulphate and silica. The plant produces distilled water with less than 10 mg/liter TDS that can be used directly for boiler feedwater with only pH adjustment.

The plant was commissioned in March of 1997 and easily passed performance tests. Actual feedwater to the equipment was slightly different than the design.

Design Water Analysis