The Facility

The project was constructed by Lockwood Greene acting as EPC under the project management of Pinnacle West Energy, an Arizona Public Service enterprise. The generating station started its operation in 2004.

Project Overview

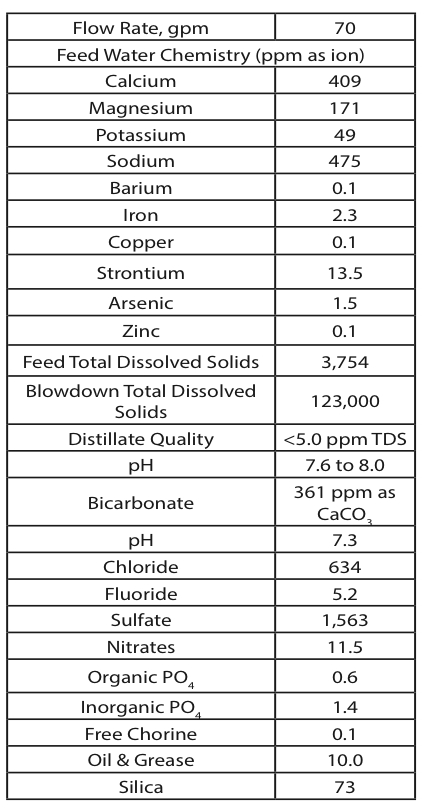

In accordance with the State of Nevada and Clark County’s strict environmental compliance requirements, this facility is permitted as a Zero Liquid Discharge (ZLD) unit. Though the facility is based on dry cooling arrangement, liquid waste is generated from the demineralizer system and other day-to-day plant operations. The generating station needed to treat 60 gpm wastewater on a continuous basis from the power generating operation plus 10 gpm from the back-up holding pond for a total design wastewater feed capacity of 70 gpm.

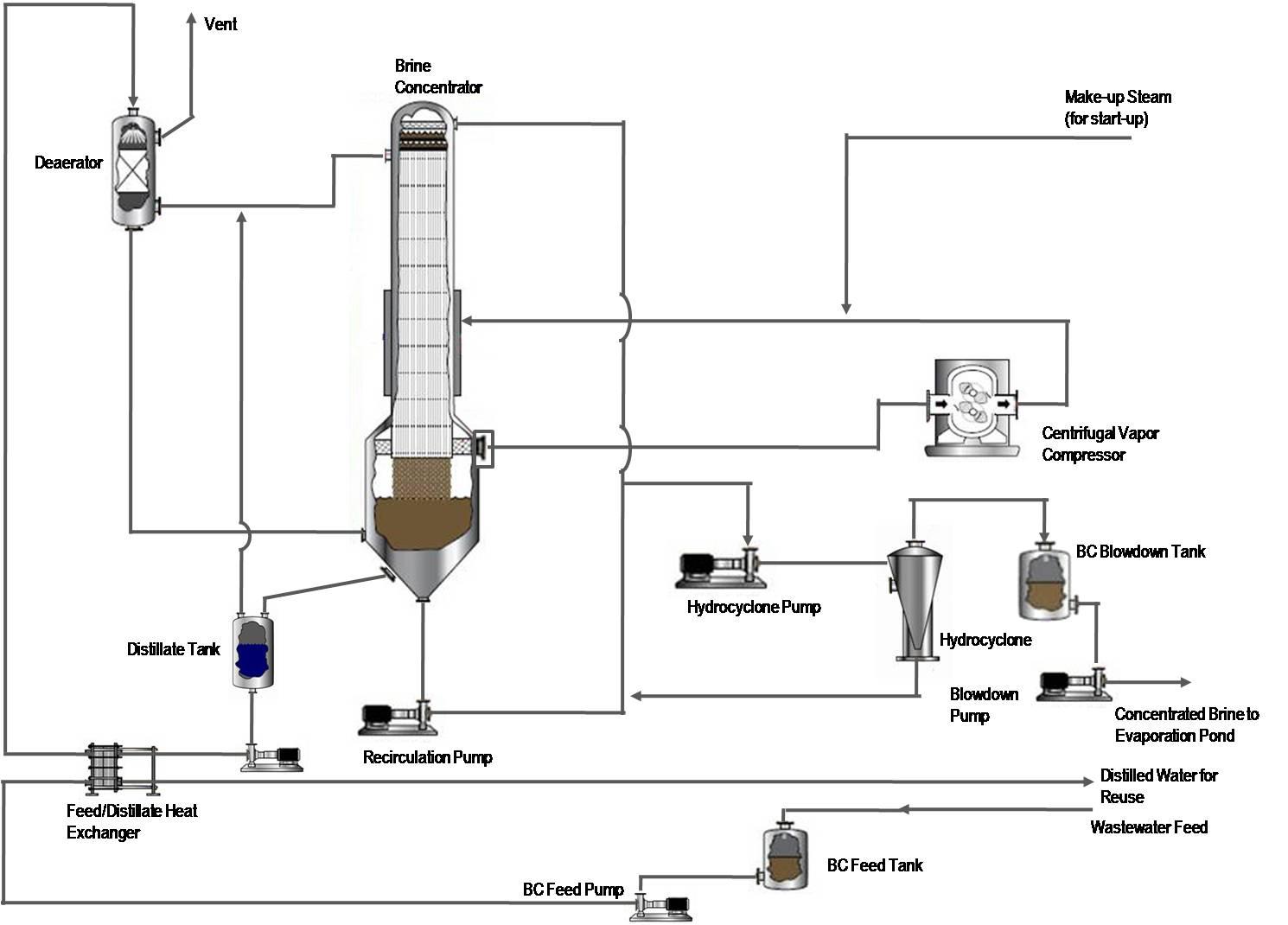

Aquatech supplied a mechanical vapor compressor driven falling film seeded slurry Brine Concentrator (BC). The Brine Concentrator is used to concentrate the generated wastewater and reduce its volume. The reduced volume is sent to the onsite solar evaporation ponds.

Scope of Service

The site uses two onsite back-up holding ponds to receive the BC underflow. High Purity distillate from the BCS is blended with Demineralizer RO permeate and further polished to generate De-Ionized water for boiler feed. A portion of the permeate and distillate blend is also used as make-up for the evaporative cooler. High TDS and saturation in low solubility scaling salts such as calcium sulfate (CaSO4) and Silica (SiO2) limit the percentage of wastewater that can be recovered in a conventional evaporator system. Aquatech designed a BC that utilizes seeded slurry evaporation technology to overcome the limitation imposed on conventional evaporators by the saturation limits of low solubility scaling compounds. The seeded slurry process establishes and maintains slurry of CaSO4 seed crystals in the evaporator re-circulating brine solution. With careful thermal and mechanical design, the CaSO4 and SiO2 co-precipitate preferentially on re-circulating seed crystals and much more slowly on the tube surface.

The evaporator at Silverhawk is uniquely designed and does not use the external addition of chemicals to maintain the seed population inside the BC. The seeding arrangement is provided for initial start up or restarts after prolonged shut downs of the unit. The BC is capable of concentrating the wastewater to near saturation in the sodium salts without scaling the heat transfer tubes. The maximum TDS used in the design of the BC is 8.2% based on the design chemistry.

The ultimate concentration achievable by the Brine Concentrator is limited by:

- System economics based on boiling point elevation of the brine

- Relative concentrations of sulfate and chloride so that the double salt, CaSO4ANa2SO4 (glauberite) does not form

- Solubility of the sodium salts.

Design Water Analysis

Process Flow Diagram