The Facility

The Ilijan Plant, developed by KEILCO-KEPCO Ilijan Corporation, is located in the Island of Luzon, about 100 miles south of Manila, Philippines. It is a combined cycle power plant and at 1,200 MW generating capacity, is the largest power plant in the Philippines.

Project Overview

The plant consists of two power blocks, which share a common membrane based Seawater Desalination system for their make-up water requirements. The desalination system sources water from the Luzon Sea and has a total installed capacity of 3.8 MGD. The offshore area consists of a sandy bottom for about 30 to 50 meters and then drops steeply to deeper waters.

Scope of Service

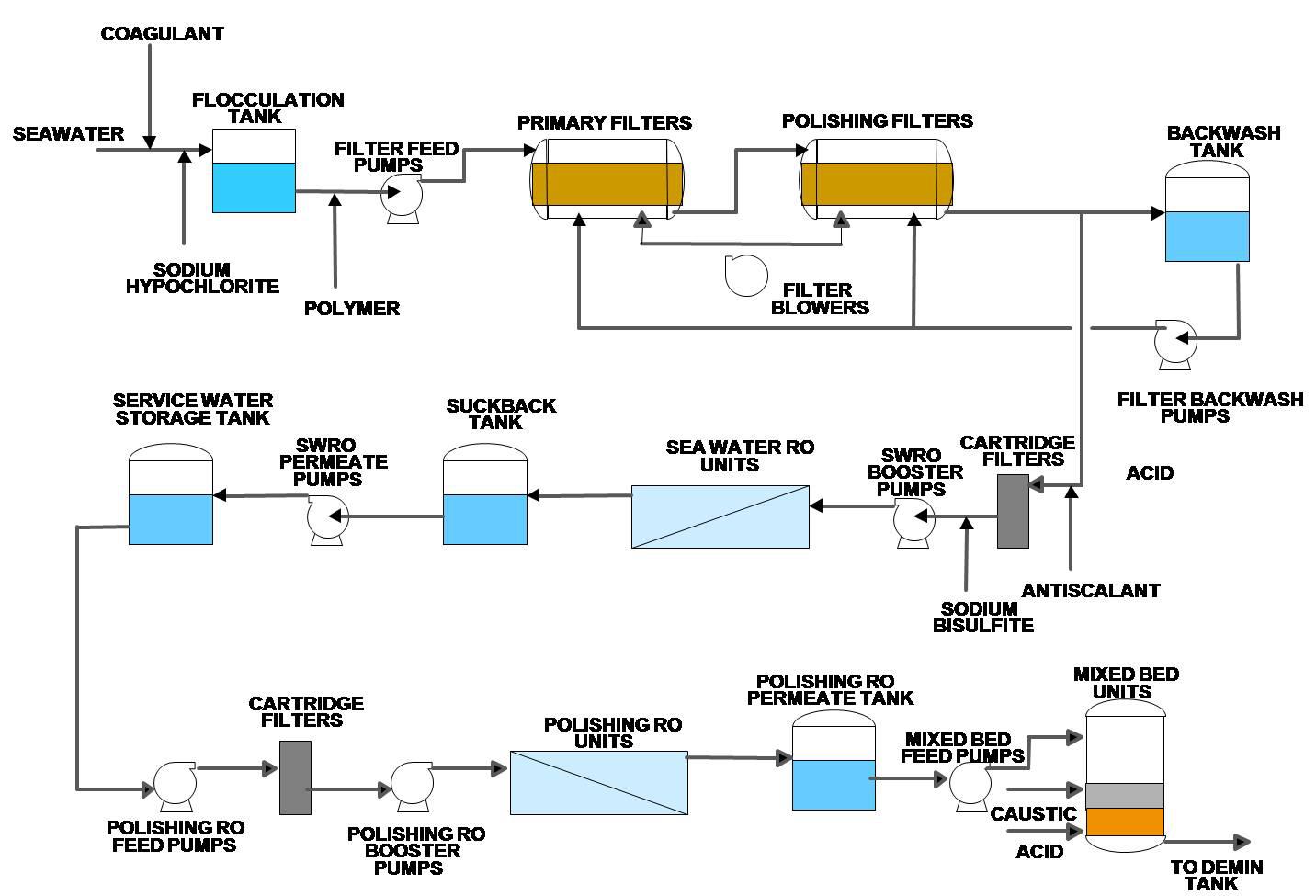

The desalination system receives chlorinated seawater; however, due to the variations in the free residual chlorine, a hypochlorite feed system was provided as part of the water treatment package. Since feed from a deep-water source is relatively low in suspended solids, BOD and Oil & Grease, the pretreatment system consists of two stage contact filtration with a flocculation tank upstream to ensure proper reaction time for the coagulant and polymer. Due to high flow rate, the dual media filters are provided in horizontal configuration and consist of a primary & polishing filter battery of 3 x 50% units.

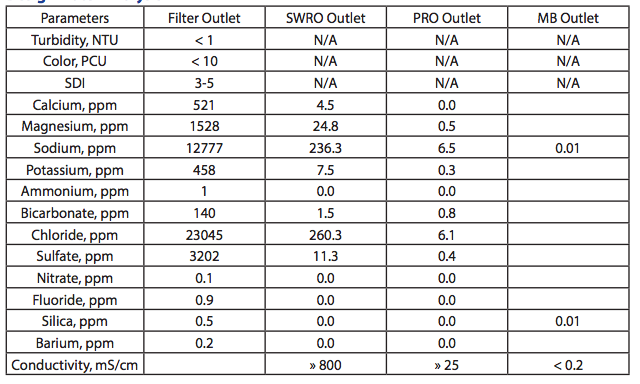

The filtered water is then processed through seawater reverse osmosis units operating in 3 x 50% configuration. The reverse osmosis booster pumps are provided with hydraulic turbocharger units as a means of energy recovery to optimize energy consumption. The raw seawater TDS is around 41,500 ppm and the seawater reverse osmosis unit is designed to produce permeate having less than 400 ppm TDS at 35% recovery. A part of the seawater reverse osmosis permeate is used for potable use and the remainder is stored in a service water tank for further polishing.

The polishing system consist of 3 x 50% reverse osmosis trains operating at 85% recovery producing a permeate of less than 10 ppm TDS. The reject from the polishing reverse osmosis trains is recycled back to the upstream of seawater reverse osmosis cartridge filters to improve the overall recovery of the system. Permeate from these reverse osmosis trains is further polished using 3 x 50% mixed bed polishers. The Mixed Bed polisher produce demineralized quality water with less than 0.2 mS/cm conductivity and is stored in the demineralized water tank.

Design Water Analysis

Process Flow Diagram