The Facility

Comission Federal de Electricidad (CFE) supplies electricity to the Mexican state of Sinaloa. An expansion of their Topolobampo generating station included the addition of three new generators producing 480 MW of power. The Topolobampo station is located 250 miles north of Mazatlan, along the Pacific Ocean coast.

Project Overview

The increased generating capacity required additional high purity boiler make-up water. Potable water was also in demand. Bufete Industrial, CFE’s contractor for the project, identified the additional water requirement to be 1200 m³/day. Bufete required the desalination plant to be energy efficient, easy to operate, compact, and skid mounted to include all integral piping, walkways and stairs. Local Mexican content was also required, to the maximum extent possible.

Scope of Service

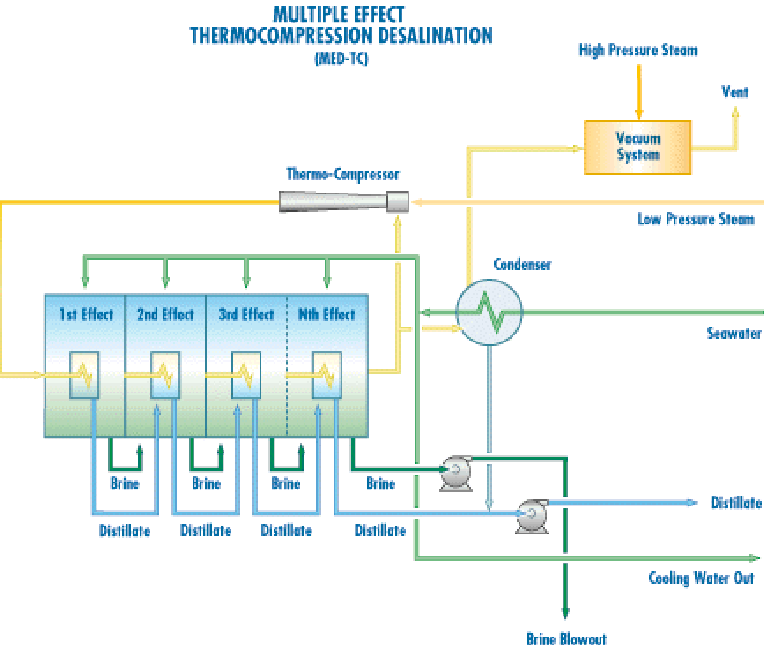

Bufete Industrial purchased two skid-mounted Aquatech Multiple Effect Thermocompression (MED-TC) desalination plants, each nominally rated at 600 m³/day of high purity distillate. Aquatech’s MED-TC technology provides an effective heat transfer design operating at low temperature for reduced scaling and enhanced plant life, while requiring approximately half the electrical energy of most other desalination systems due to lower seawater requirements and, therefore, smaller pumps. The units are fully automated and require minimal operator attention. Aquatech took advantage of Mexican steel fabrication facilities to meet CFE’s maximum local content requirement. Fabrication of the desalination plant skids, including the installation of pumps, associated piping, valves, and instrumentation was completed in Mexico. Start-up of the MED-TC units was in August 1994. Both units passed all performance criteria including steam consumption and distillate quality of less than 5 ppm total dissolved solids (TDS). The high purity distillate is either sent to the polishing demineralizer for use as boiler make-up or is used as potable water.

Process Flow Diagram