The Facility

Southern Peru Copper Company’s (SPCC) facility located in Ilo, Peru requires high purity water for boiler make-up at the smelter power plant. Process water for various smelter and mining operations and potable water for the town and Port of Ilo is also needed.

SPCC’s first Aquatech long tube multistage flash (MSF) seawater desalination plant producing 720,000 USGPD was commissioned in 1966. This was followed by a second MSF plant in 1976 with a capacity of 960,000 USGPD.

Project Overview

The ocean off the southern coast of Peru is noted for being some of the world’s richest fishing waters. Immediately south of the Ilo facility and in direct flow with the prevailing current are enormous guano deposits which cause the water to be high in nitrates and ammonia, and is the main reason why these waters are so plentiful with fish.

Pre-design concerns about this project were focused on the potential problems associated with the highly polluted feedwater. In addition, frequent occurrences of “red tides,” where Deep Ocean biological matter comes to the ocean surface, causes severe anaerobic conditions which create the potential for highly corrosive conditions.

Scope of Service

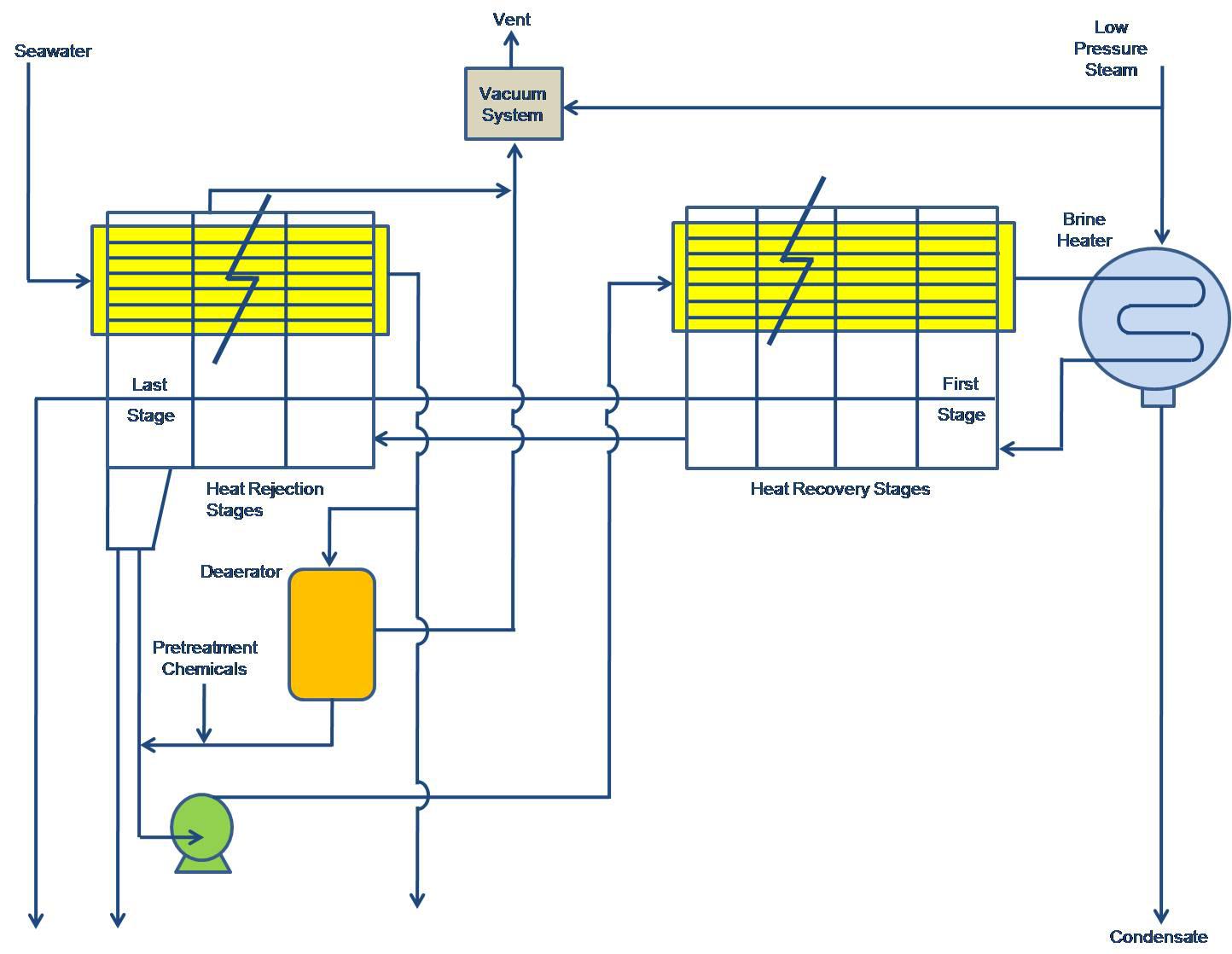

Prior to the design of the first MSF plant, Aquatech conducted a thorough study. Water chemistry profiles were developed to determine potential fouling problems. With the result of these studies in hand, Aquatech proceeded with the MSF plant design. A key factor was the assurance of proper deaeration and vent system design. The acidified seawater emits significant amounts of carbon dioxide which is released and vented off in the deaerator. The materials of construction chosen for the evaporator, operating at a top brine temperature of 230°F, included 90/10 CuNi tubes and tubesheets, with mild steel shells.

The first Aquatech MSF plant commissioned at SPCC has now been in operation for over 30 years. The second unit has been in operation for over 20 years. Both systems still have the original tubes and carbon steel shells. Plant reliability and performance have been outstanding, with recorded historical on-line times exceeding 90% at design capacity and product purity. The shell material selection is testimony to the fact that carbon steel, when in a properly controlled environment, does have a long life expectancy and can do an excellent job in high temperature seawater MSF plants.

Process Flow Diagram