The Facility

CNOOC and Shell Petrochemicals Company Limited (CSPC) made petrochemicals history in China by building and operating a USD 4.3 billion petrochemicals complex in Daya Bay, Huizhou Municipality, Guangdong Province. It is the largest capital investment for a Sino-foreign joint venture project to date in the People’s Republic of China. The joint venture partners are Shell Nanhai BV, a member of the Royal Dutch/Shell Group of Companies and CNOOC Petrochemicals Investment Limited (CPIL). CPIL is owned by China National Offshore Oil Corporation (CNOOC) and Guangdong Investment & Development Company, an investment company authorized by the People’s Government of Guangdong.

Project Objective

The objective of the project was to fulfill the huge need for water to the CSPC Nanhai Petrochemical facility in accordance with project specification, quality assurance, and project requirement for safety, reliability, maintainability, operability, environmental compatibility and continuity of operation. After a thorough system evaluation process, CSPC Petrochemicals selected Aquatech International Corporation’s Ultrafiltration, Demineralization, Potentially Contaminated Condensate and Normally Clean Condensate System, which was based on Aquatech’s vast experience in Water Treatment.

Scope of Service

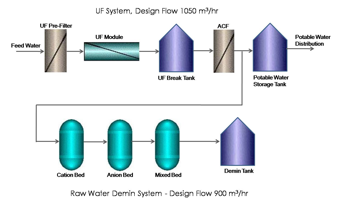

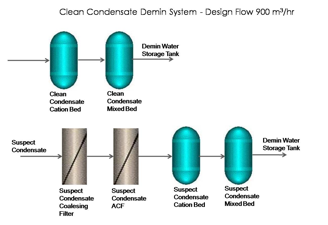

The water treatment design for CSPC Petrochemicals consists of six trains of Ultra filtration, followed by Activated Carbon Filters which produce 1050 m³/hr. The Raw Water Demineralization system consists of three trains which produce 900 m³/hr. The Normally Clean Condensate and Potentially Clean Condensate Systems produce 900 m³/hr each. By maintaining its quantity requirement, it also maintains its quality. The feature is simplicity of design which makes it very easy for the operator to understand and operate the plant. All three systems (Demin, NCC, PCC) are connected to the DCS (distributed control system) of CSPC so it can be easily operated. Since the design is simple, it makes it very easy to maintain the plant which also reduces the operation and maintenance cost. The major constraint was delivery of the system. Though the system consisted of six ultrafiltration trains, around 35 vessels and huge piping, Aquatech was able to construct, fabricate and commission the system in 50 weeks which was well within the project schedule.

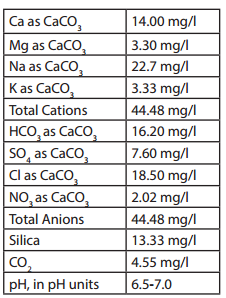

Design Water Analysis

Process Flow Diagram