The Facility

Pragati Power Corporation Limited, formerly Delhi Vidyut Board (DVB), was formed by the Government of National Capital Territory (NCT) of Delhi in 1997 for the purpose of generation and distribution of power to the entire area of NCT of Delhi. To bridge the gap between demand and supply and to have reliable power supply to the capital city of Delhi, a 330 MW combined cycle Gas Turbine Power Project – Pragati Power Project (PPP) – was set up on a fast track basis. National Thermal Power Corporation (NTPC), the largest thermal power generating company of India, was the consultant for this project. Raw water requirement in this plant is met through sewage treated water being drawn from various sources including a Sewage Treatment Plant. The de-mineralized water requirement for steam generation is met up through sewage treated water by treating it through Reverse Osmosis De-Mineralized Process (RODM).

Project Overview

The plant is located on the banks of River Yamuna, the main potable water source of the city. In view of huge water demand for the power plant, direct intake from the river was not feasible. Due to paucity of water the PPP plant was designed to operate on treated sewage as feed water, thus conserving already scarce natural water resources. DVB, after exploring various options, selected Aquatech’s RO System for water reclamation at the plant.

Scope of Service

The Aquatech plant at PPP treats tertiary treated sewage and purifies it for boiler make up, which is very high purity water. Aquatech designed and built a plant that made 2 x 1200 m³/day of BFW. This system consisted of: Cascade Aerator; Twin Bed Gravity Filters followed by Activated Carbon Filters with all the associated coagulant chemical dosing skids; Cartridge Filter outlet at SDI < 4; two pass Reverse Osmosis trains operating at 88% recovery in stage I and 90% recovery in stage II; followed by mixed bed Ion Exchange Unit. Since start-up in 2003, the performance of the plant has been outstanding with no requirement of membrane replacement for over five years. The high recovery of 88% is now considered to be an industry benchmark in producing BFW by tertiary effluent waste water reclamation.

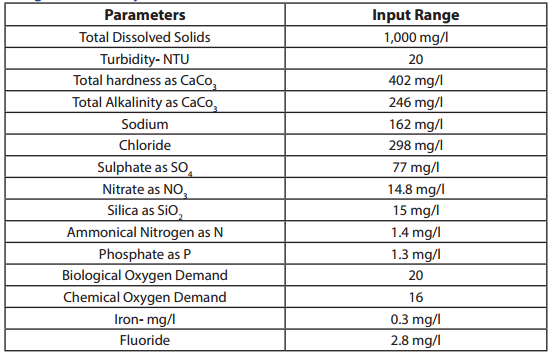

Design Water Analysis

Process Flow Diagram